In the world of precision lighting, the "heart" of the fixture is the LED, but the "soul" is the lens. For lighting architects, industrial designers, and product engineers. Selecting the optical lens that best suits your lighting project from COB (Chip-on-Board) or Single Lens (Discrete SMD) options can effectively reduce costs and accelerate project development progress.

This choice not only determines the brightness (lumens) but also influences beam quality and thermal management strategy. Whether you are designing PAR lighting, dynamic stage lighting, or precise architectural wall washers, understanding the physics behind these two technologies is crucial.

As an optical design company and precision mold manufacturer with over a decade of experience, ASAHI not only understands the fundamental definitions but also delves into the engineering principles underlying these solutions.

The Single Lens Architecture

(Best Applications: Wall Washer Lights, Landscaping, Architecture, Flashlights, Stage Lights)

When we speak of a "Single Lens" solution, we refer to a distributed array architecture where one LED chip (SMD) is paired with one dedicated optical lens.

1. The Physics: Total Internal Reflection (TIR)

From an optical designer’s perspective, Single Lens optics rely on a principle called TIR (Total Internal Reflection).

Imagine a water slide. If you design the curves perfectly, the water (light) stays inside the slide until it exits at the bottom, without spilling over the edges. A high-quality single lens acts like a funnel. It sits directly on top of a small LED source (like a 3535 or 5050 package). Because the light source is small, the lens can capture virtually 100% of the photons and force them into a highly controlled path. This allows us to "sculpt" light with extreme precision.

2. Engineering Specific Beam Shapes

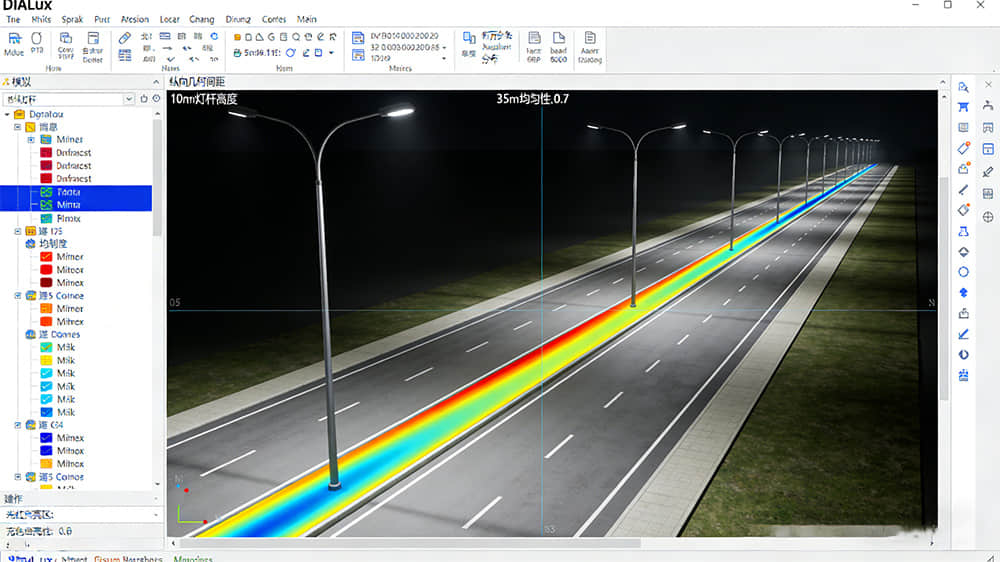

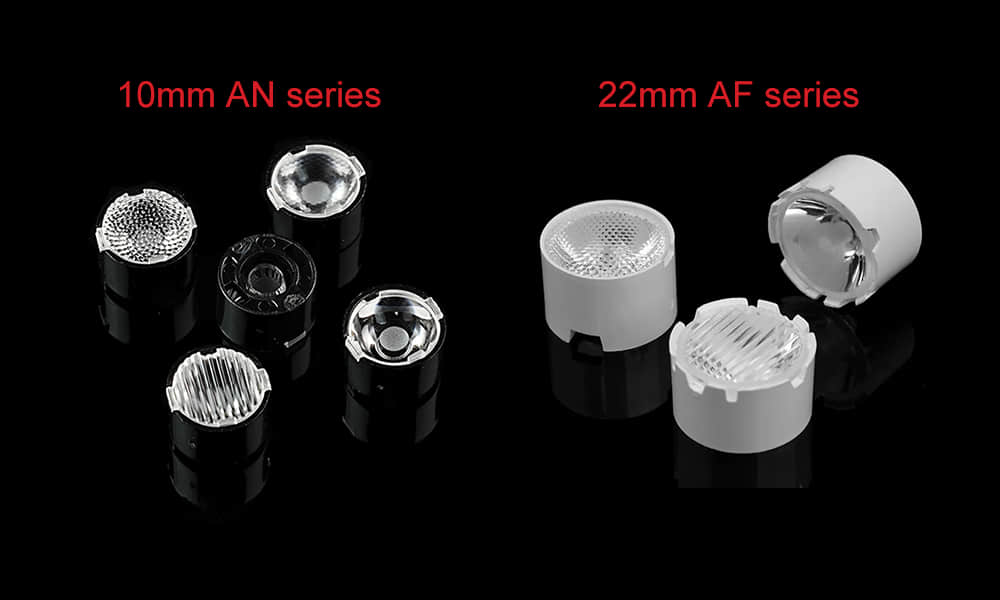

The "Grazing" Effect for Architecture (Wall Washers): In architectural lighting, specifically Wall Washers, the goal is to illuminate a tall vertical surface evenly without creating "hot spots" at the bottom or spilling light into the night sky. A standard round beam cannot do this efficiently. This is where our AN Series shines. Despite its compact 10mm diameter, we engineered the mold surface with a micro-structured texture to stretch the light into a 15x60° elliptical beam. This "blade" of light allows architects to graze walls from top to bottom with uniform intensity, perfectly highlighting the texture of stone or brick.

The "Throw" for Flashlights and Landscaping: For Flashlights or long-distance Landscaping Lights, the priority is "collimation"—making the light rays run parallel to travel further. The larger the lens, the better the control. Our AF series features a 22mm diameter, which provides a larger optical surface area. This allows it to effectively control high-power, high-brightness LEDs (like 5050 chips). The AF series offers up to 10 different beam angles to choose from (10°, 15°, 25°, 30°, 40°, 60°, 80°, 10x45°, 10x60°, 30x60°), meeting your diverse lighting needs and helping you effortlessly realize projects such as Wall Washer Lights, Landscaping Lights, and Architectural Lighting.

Color Mixing in Stage Lighting: In dynamic Stage Lights, engineers often use RGBW (Red, Green, Blue, White) chips. If you use a simple reflector, you might see a "rainbow effect" at the edge of the spot. A high-quality single lens with a frosted top surface mixes these colors inside the lens medium, ensuring that the light exiting the fixture is a perfectly blended, pure color.

The COB Architecture

(Best Applications: Commercial PAR Lights, Track Lights, Downlights)

COB (Chip-on-Board) technology represents a different philosophy. Instead of separating the chips, COB packs hundreds of tiny LED dies directly onto a single substrate, creating one large, circular glowing area.

1. The Physics: Refraction and Reflection

Because the Light Emitting Surface (LES) of a COB is large (often 6mm to 30mm), we cannot use the TIR (Total Internal Reflection) principle as easily as with small SMDs. Instead, COB optics typically rely on Refraction (bending light through a large glass or PMMA lens) or Reflection (using a reflective cup).

The goal here is not to create a complex rectangular shape, but to deliver Maximum Center Beam Candlepower (CBCP) and Visual Comfort.

2. Advantages of COB Single Light Source

- High Contrast for Retail (PAR Lighting): In a jewelry store or a clothing boutique, you want the merchandise to sparkle. This requires a beam with a very high intensity in the center that fades gently to the edges. Our 35mm COB LED Optical Lens For PAR Lighting is engineered specifically for this standard size. By focusing the massive lumen output of a COB into a 24° or 38° beam, we create a spotlight effect that draws the customer's eye directly to the product, creating a high-end commercial atmosphere.

- The "Single Shadow" Advantage: This is the most significant advantage of COB in human-centric environments. If you use a cluster of multiple single lenses above a dining table, you might see "multi-shadows" (ghosting)—where one fork casts five faint shadows. It looks unnatural and dizzying. A COB behaves like the sun: it is a single source. Therefore, it casts one single, sharp, and natural shadow. For general lighting in hotels or homes, our extensive range of COB Lens options ensures a glare-free, comfortable visual experience.

The Engineer's Perspective: Thermal & Mold

As a manufacturer, we must also look at the "hidden" factors that affect your product's cost and longevity.

1. Thermal Management (Heat Flux Density)

Single Lens (Cooler & Lighter): In an SMD architecture (using AN or AF series), the heat sources are spread out across the entire PCB board. The "Heat Flux Density" is low. This means you can often use a lighter, thinner aluminum housing for your flashlight or wall washer, reducing material costs.

COB (Hotter & Heavier): A COB generates a massive amount of heat in a very small area (e.g., 50 Watts in a 20mm circle). To prevent the chip from burning out, you need a heavy, high-efficiency heatsink (often copper-core) to conduct that heat away rapidly. This adds weight and cost to the fixture.

2. Mold Precision & Manufacturing

The Single Lens Challenge: Creating a lens like the AN Series (15x60°) requires extremely high mold precision. The surface roughness (Ra) must be polished to nano-levels to ensure the light stretches evenly without scattering. At Asahi Optics, we use ultra-precision diamond turning machines to cut these molds in-house.

The COB Lens Challenge: COB lenses are often larger and thicker. The challenge here is "shrinkage." During injection molding, thicker plastic shrinks as it cools. If not controlled, this alters the beam angle. Our process engineers strictly control the cooling cycle to ensure every 35mm COB Lens maintains its exact optical properties.

Final Comparison Table

| Feature | Single Lens (SMD Architecture) | COB (Chip-on-Board Architecture) |

|---|---|---|

| Optical Principle | TIR (Total Internal Reflection): 90%+ Efficiency. | Refraction/Reflection: Focus on mixing and smoothing. |

| Beam Shaping | High Flexibility: Elliptical (15x60°), Asymmetric, or Tight Spot (10°). | Standard: Mostly Circular (Spot, Flood, Wide Flood). |

| Shadow Quality | Potential for faint multi-shadows (solved by frosted surfaces). | Perfect Single Shadow: High definition, natural look. |

| Thermal Load | Distributed: Low heat density, easier to cool. | Concentrated: High heat density, requires heavy heatsinks. |

| Key Applications | Wall Washers, Flashlights, Landscape Spotlights, Stage Lights. | PAR Lights, Downlights, Track Lights, Museum Lighting. |

| Recommended Product | AN Series / AF Series | 35mm COB Lens / COB Lens Series |

Conclusion

There is no "winner" between COB and Single Lens—only the right tool for the job.

If you need to slice light into a narrow strip to wash a building, the physics of the Single Lens (SMD) is your best ally. If you need to create a warm, high-contrast, and perfectly shadowed atmosphere in stores or restaurants, COB may fulfill your illumination needs.

At Asahi Optics, we bridge the gap between design and manufacturing. Whether you need standard off-the-shelf lenses or a custom mold developed for a unique application, our optical engineers are ready to assist you.