At present, there are different types of street lights manufactured by various companies which are made to fulfill several applications within the broader Outdoor Lighting sector. As a sub-category of outdoor illumination—alongside Area Lighting, Billboard Lighting, and Tunnel Lighting—Street Lighting carries the most rigorous requirements for public safety and long-term durability.

In order to illuminate numerous outdoor areas, there are street lights specially made for roads, highways, and residential paths. However, it can get confusing to choose the ideal type of light for market needs if one is not aware of the specific LED optics design that distinguishes roadway lighting from general area illumination. People may wonder about what type of lights are street lights, what type of bulbs are used, and what are their unique pros, cons, and applications in modern infrastructure.

Street lights, also known as street lamps, are elevated light sources essential for illuminating roadways, walkways, and other public thoroughfares. While other Outdoor Lighting categories like Area Lighting focus on broad, 360-degree coverage for plazas, or Billboard Lighting focuses on high-intensity focal beams, Street Lighting is specifically engineered for linear uniformity and glare control to assist drivers and pedestrians.

By enhancing visibility in dark spaces, street lights significantly improve security and driving safety. They are often used alongside traffic safety devices to increase the visibility of road barriers, pedestrian crossings, and poorly lit intersections. The primary purpose of streetlights is to provide reliable illumination to areas that are dark and difficult to navigate at night, using various technologies—including LED, high-pressure sodium (HPS), and metal halide—to achieve the desired light quality and temperature.

In the competitive global market of 2026, the technical specifications of street lighting have become the benchmark for project tenders. Here are the typical features to consider:

The history of street lighting is a journey from fire to photons, reflecting the progress of urban safety.

This section explores the various technologies co-existing in the 2026 market, detailing their pros, cons, and specific applications for optimal outdoor illumination.

| Type of Light | Pros | Lifespan | Best Outdoor Application |

| Incandescent | Affordable, CRI 100 | Short (<2,000h) | Sentimental/Village paths |

| Fluorescent | Less heat, more efficient | 7,500-20,000h | Older parking lots |

| Mercury Vapor | Bright, durable | Varies | Legacy high-mast lighting |

| HPS (Sodium) | Long life, productive | 24,000h | Industrial roadways |

| Metal Halide | Bright, crisp white light | 12,000h | Sports and Area lighting |

| Solar Street Light | No electricity, eco-friendly | 15-20 years | Rural/Remote highways |

| Advanced LED | Max efficiency, precise optics | 100,000h | Smart Cities & Highways |

Since Thomas Edison created incandescent light more than a century ago, it has largely had a similar design, generating light via a tungsten filament. They are relatively ineffective and extremely hot to the touch. While a few villages continue to use them for sentimental appeal, they are not recommended for modern infrastructure.

#2 Mercury Vapor & Fluorescent Lights

Fluorescent lights emit light by passing electricity via a gas, resulting in the phosphor coating within the tube shining. Mercury vapor lamps, identifiable by their bluish-green glow, were once a staple for big spaces like streets and stadiums. However, they are risky due to the presence of mercury and dangerous UV radiation if the outer quartz tube breaks.

#3 High-Pressure Sodium (HPS) Street Lights

HPS lamps are high-intensity discharge bulbs that produce an orange-white light. Preferred for indoor gardening and security, they have an efficiency of 100-150 lm/W. However, their poor color rendering makes them inferior to LED for modern roadway safety.

#4 Solar Street Lighting Systems

Photovoltaic technology is used in solar street lighting systems to renovate sunlight into DC power. For illuminating streets in isolated settlements, solar systems are suitable as they require no electricity and carry a longer lifespan with tubular batteries. These systems rely heavily on high-transmittance LED optical lenses to maximize the limited energy stored during the day.

Compared to earlier lighting systems, LED streetlights can save between 30% and 70% of energy. LEDs do not “burn out” like incandescent bulbs; instead, they suffer from “lumen depreciation,” where brightness gradually decreases over 50,000 to 100,000 hours.

The "magic" happens when an electrical current flows through a microchip, igniting the tiny light sources known as LEDs. To deter performance difficulties, the heat generated is consumed in a heat sink. Most importantly, several LED streetlights include a secondary lens on the LED panel that is made to cast light in a specific rectangular structure. This is the core of Asahi Optics—our custom LED optics design ensures that light is never wasted on the surrounding area or the sky, but is focused purely on the pavement.

In the broader category of Outdoor Lighting, the defining factor for street lighting is the precision of its “Secondary Optics.” While the LED chip (Primary Optics) provides the raw light, it is the LED optical lens (Secondary Optics) that shapes that light into a functional beam.

At Asahi Optics, we utilize advanced refractive and reflective technologies to ensure that light is not merely “bright,” but “directed.” By mastering the interaction between the light source and the lens material, we achieve a light efficiency of over 90%, ensuring every watt is used to enhance road safety.

To help our global clients navigate the “confusing” market, we strictly adhere to the IESNA (Illuminating Engineering Society of North America) standards. For Street Lighting, choosing the right distribution type is critical to meeting municipal requirements like EN 13201 or NBR 5101.

Type I is a symmetric, lateral distribution designed for narrow paths where the light pole is located near the center of the walkway. It projects light in two directions along the length of the path.

Type II is intended for narrow streets or entrance ramps where the road width is roughly equal to the mounting height of the pole.

Asahi Advantage: Our Type II Medium (T2M) lenses, such as those found in the ALST173 series, provide an excellent longitudinal spread that is preferred for European residential streets.

Type III is the most widely utilized distribution for general roadway lighting. It projects light forward to cover the width of the road while maintaining a wide “Batwing” lateral spread to allow for maximum pole spacing.

Why it matters: This pattern reduces the number of poles needed for a project, significantly lessening operational and installation expenses.

Commonly referred to as “Forward Throw,” Type IV is used for perimeters or when the pole is located far from the edge of the road. It pushes light far forward with minimal backlight.

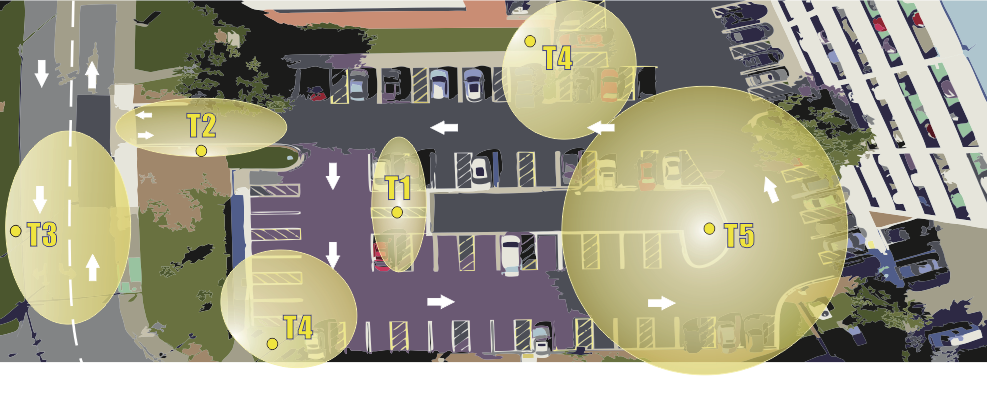

Type V provides a circular or square pattern. While frequently used in Area Lighting for parking lots and plazas, in Street Lighting, it is the go-to choice for large highway intersections and roundabouts.

For more detailed IESNA standards, please proceed to: What are the light distribution types of T1, T2, T3, T4, and T5 defined by IESNA?

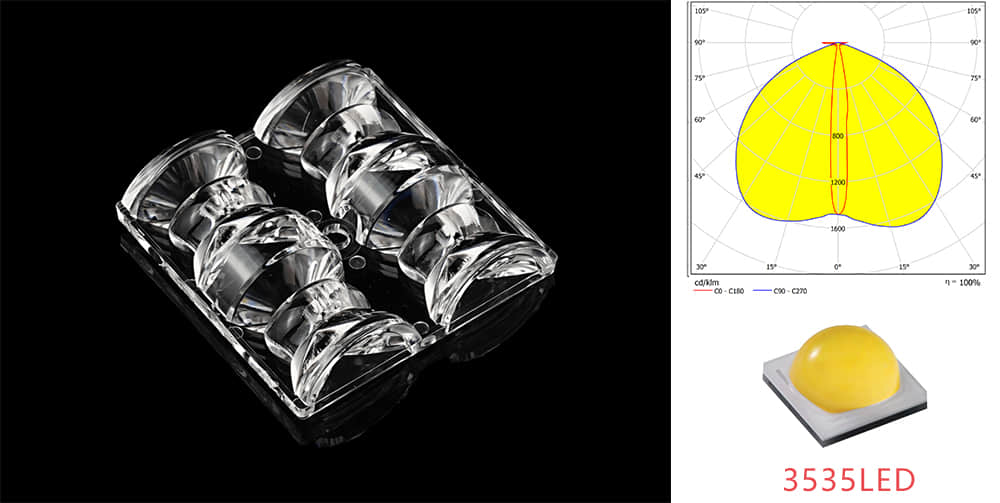

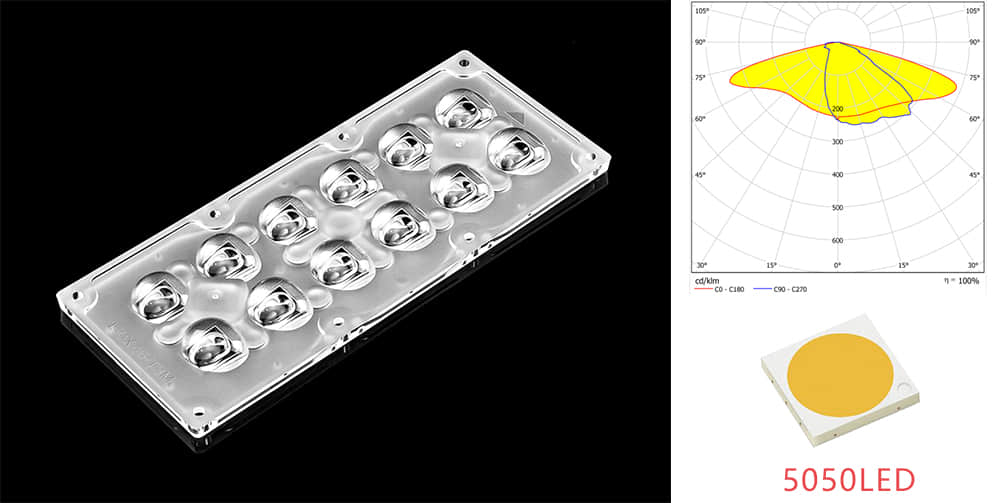

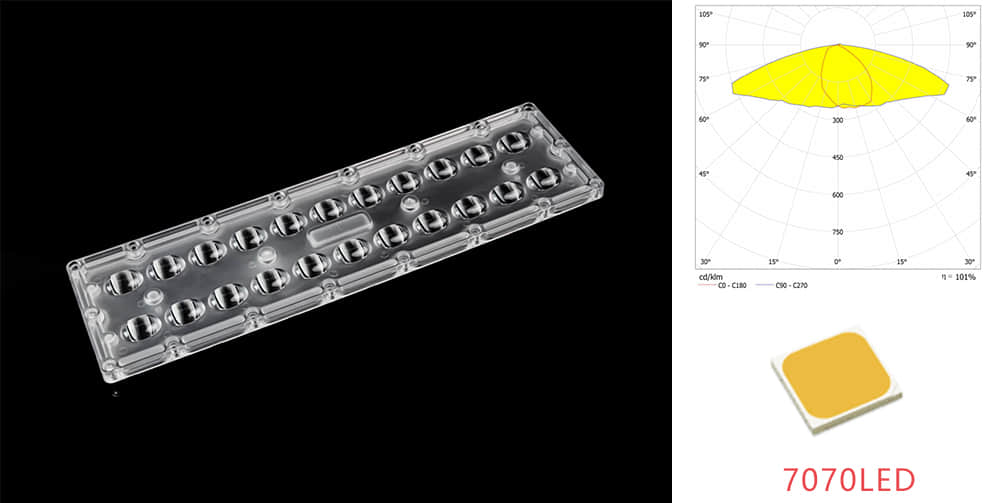

A unique strength of Asahi Optics is our ability to design lenses that are compatible with a full range of LED chips, from 3535 and 5050 to the high-power 7070 LEDs.

The 2x2 modular array is the building block of modern street lighting.

Model Focus: AJST50D4LED15110G.

Features: Compact 50mm size, 4in1 design, and highly compatible with 3535 LED chips.

Application: Ideal for residential roads and urban paths where a modular approach allows for easy fixture maintenance and scalability.

For high-wattage street lighting, the 2x6 integrated array is the industry favorite.

Model Focus: ALST173D12LED5050T3M.

Features: Integrated IP67 waterproof silicone gasket, durable Optical PC material, and a perfect Type III Medium distribution.

Application: Designed for main city arteries and industrial zone lighting where reliability under various weather elements is non-negotiable.

The 7070 LED is becoming the trend for super-high-mast and highway lighting due to its immense lumen output.

Model Focus: AJST304D22LEDT2.

Features: Specialized optics for large-surface LEDs, maintaining a sharp “Cut-off” to reduce glare despite the high brightness.

Application: Multi-lane highways and high-speed interchanges where “super bright” lighting is required for maximum safety.

The quality of a street light is measured by its Uniformity Index (UI) and Glare Control (BUG Rating).

Uniformity: Asahi’s customized LED lens designs aim for a UI > 0.8. This ensures that the road surface appears as a continuous “carpet of light,” improving the driver's ability to react to obstacles.

Glare Control: Excessive glare can blind drivers. Our lenses feature a “Cut-off” design that strictly limits light intensity at high angles (above 80°). This not only enhances safety but also ensures “Dark Sky” compliance, protecting the surrounding area from light pollution.

In the realm of Outdoor Lighting, materials are the first line of defense against the environment. While PMMA is excellent for indoor or low-impact applications, Street Lighting almost exclusively demands Optical PC (Polycarbonate).

At Asahi Optics, we don't just use “any” plastic; we select specific high-performance PC resins to ensure 10-year durability. PC is preferred for street light lenses because:

High Heat Resistance: Street lights, especially those using high-power 7070 LEDs, generate significant heat. PC can withstand operating temperatures up to 120°C without deformation.

Impact Resistance (IK Rating): Outdoor fixtures are prone to vandalism or falling debris. PC offers an IK08 to IK10 rating, making it virtually unbreakable compared to glass or PMMA.

UV Stability: We use UV-stabilized PC to prevent the “yellowing effect” caused by prolonged exposure to intense sunlight in regions like South America and Southern Europe.

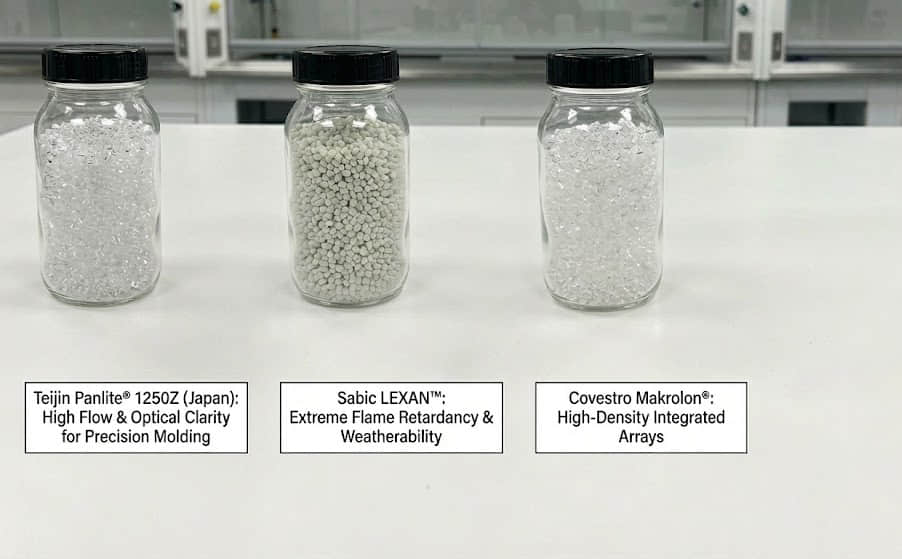

Asahi provides the flexibility to specify materials based on project requirements. We maintain deep partnerships with global material giants:

Teijin (Japan): Specifically the Panlite® 1250Z series, renowned for its high flow and optical clarity in precision lens molding.

Sabic (LEXAN™): Used for projects requiring extreme flame retardancy and weatherability.

Covestro (Makrolon®): Ideal for high-density integrated lens arrays.

Whether your project requires Flame Retardant (V0 rated), Diffused, or High-Transmittance Clear PC, Asahi can manufacture lenses using your designated material to ensure consistency with your supply chain.

Winning a municipal tender requires more than just a bright light; it requires documented compliance. Asahi Optics acts as your technical consultant to meet the following regional standards:

Europe (EN 13201): We design optics that strictly control the G-rating (Glare) and ensure Uniformity (Uo/Ul) levels required for M1 to M6 road classes.

North America (IESNA): Our lenses are engineered to achieve high BUG (Backlight, Uplight, Glare) ratings, ensuring "Dark Sky" compliance.

Brazil & South America (NBR 5101): We understand the specific requirements for lateral spread and thermal resilience in high-humidity tropical environments.

By providing full IES files and Dialux simulations, we ensure that your fixtures pass laboratory testing on the first attempt.

Choosing an optics manufacturer involves mitigating risks. Here is how Asahi solves common customer anxieties:

The Cause: Poor mold precision or material shrinkage during cooling.

Asahi Solution: We utilize high-precision CNC mold-making and constant-temperature injection environments. Our independent mold development ensures that the physical lens matches the optical design with a tolerance within microns.

Asahi Solution: This is our core strength. We specialize in custom LED optics design. If our standard 2x2 or 2x6 arrays don’t align with your PCB or housing, we can modify the structure while maintaining the IES profile.

Asahi Solution: Time is money. We offer a 25-day rapid development cycle from design to hard-tooling, allowing you to move from prototype to mass production in record time.

As we have explored in this 4,000-word roadmap, Street Lighting is the most technically demanding segment of the Outdoor Lighting industry. It requires a perfect synergy of high-power LED technology, thermal management, and—most importantly—precision optical design.

Every street lighting project requires perfectly matched optical lenses to support it. Contact the best LED street light optical lens manufacturer for solutions.

Asahi Optics welcomes your questions, inquires and feedback. Please use the form below or contact us at any of the addresses below. Our sales team will get back to you shortly.