Engineered specifically for linear LED lighting systems, this optical solution provides optimal uniformity, adaptable design options, and cost-efficient performance for advanced indoor illumination applications.

An extrusion linear lens is a specialized, continuous, and slender optical component designed for linear LED luminaires. It is manufactured through a continuous extrusion process where material is pushed through a shaped die.

Its core cross‑sectional profile is precisely engineered to guide and diffuse LED light, forming a long, seamless band of illumination. By effectively controlling and redistributing light emitted by LEDs, extrusion lenses meet specific requirements for beam shape, uniformity, and glare reduction in targeted lighting applications.

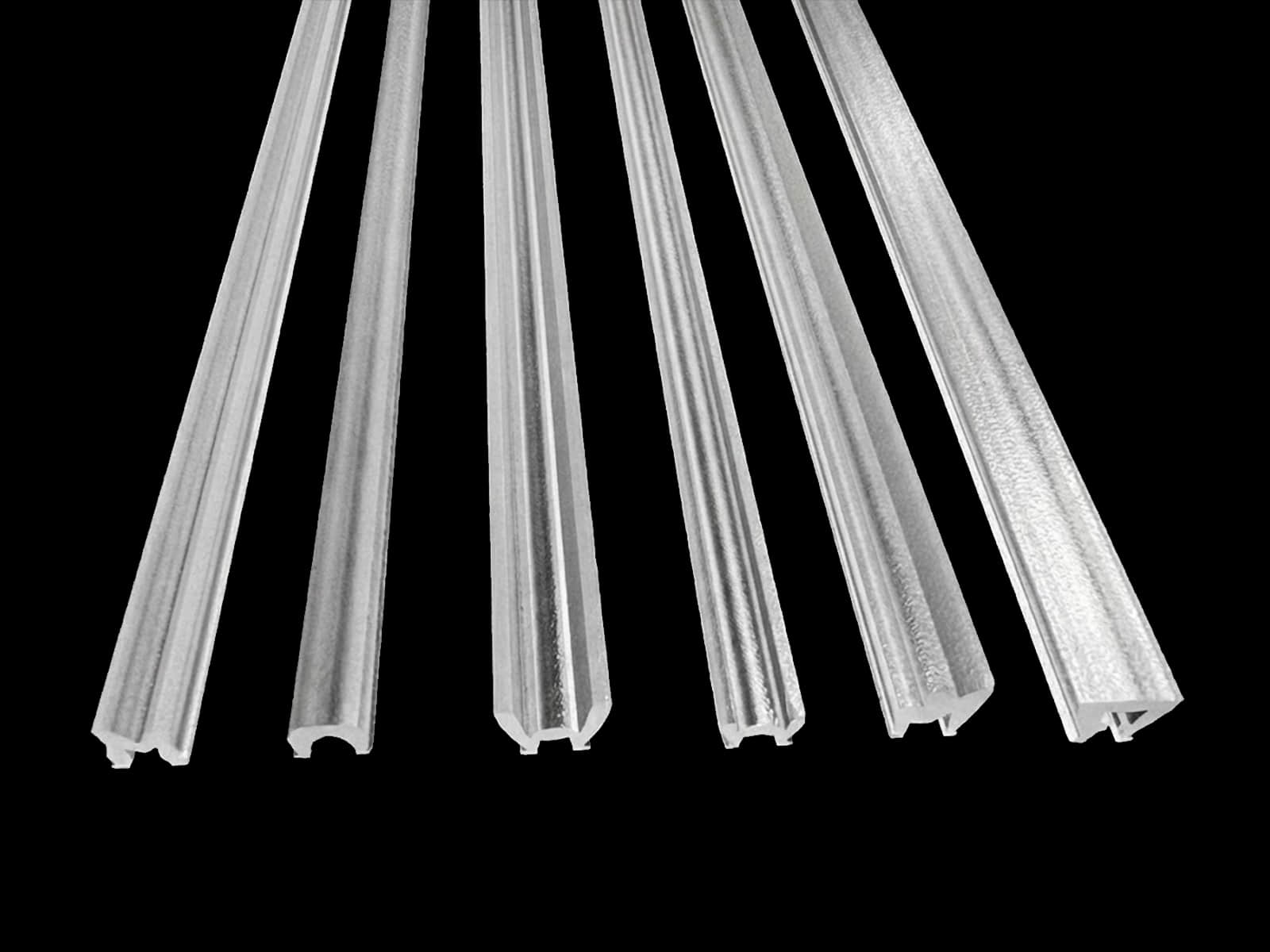

By altering the cross‑sectional design of the extrusion die, a wide range of complex light distributions can be achieved, such as batwing distribution, asymmetric distribution, and symmetric wide‑angle beams. This enables fluid, modern lighting designs that can run continuously and even navigate corners, meeting diverse needs from basic illumination to accent wall‑washing and commercial lighting.

Through precisely designed optical surfaces, direct LED brightness is significantly reduced while the effective light‑emitting area is increased. This effectively lowers the Unified Glare Rating (UGR), achieving higher levels of visual comfort. Ideal for environments with strict glare‑control requirements, such as offices, schools, and hospitals.

Extrusion is a highly efficient continuous production process. Once the die is completed, lenses can be rapidly produced in large quantities at low cost per meter, making it particularly suitable for long‑length linear luminaires. Compared to individually mounted lenses per LED or long‑length injection‑molded lenses, the per‑meter cost is highly competitive.

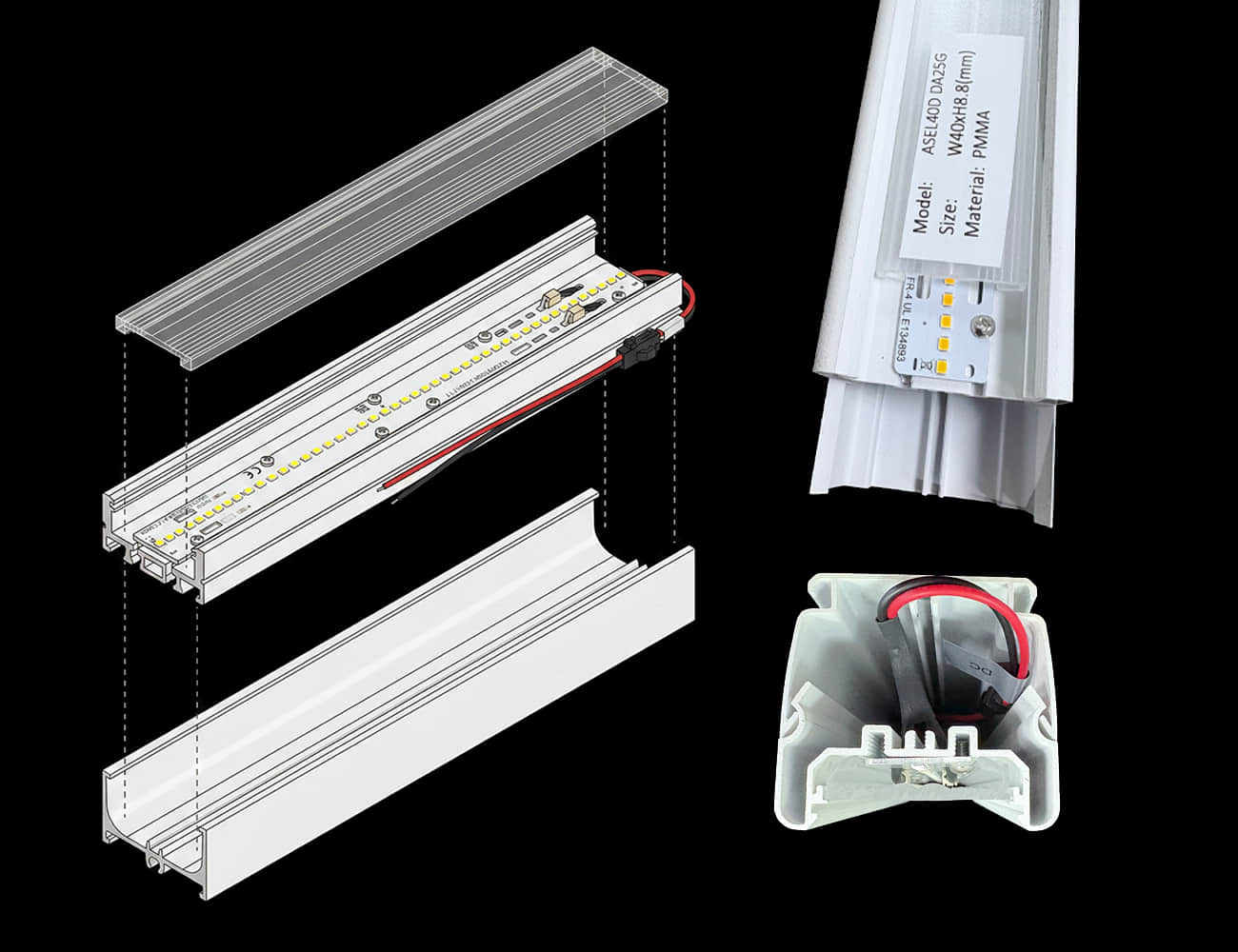

A single extruded linear lens can cover an entire row of LEDs, simplifying the internal mounting structure. It integrates seamlessly with LED light boards and aluminum heat‑sink profiles, forming a modular, all‑in‑one solution that enhances assembly efficiency and overall sealing of the luminaire.

This is its most prominent strength. It seamlessly blends discrete LED point sources into a continuous, soft light band free of dark zones or granular appearance, offering far superior visual quality compared to solutions that rely on individually assembled lenses. It is especially suited for high‑quality ambient lighting and uniform task‑lighting applications.

This exploded view illustrates how the extrusion linear lens integrates with aluminum profiles to create a complete lighting module with efficient heat dissipation and structural stability.

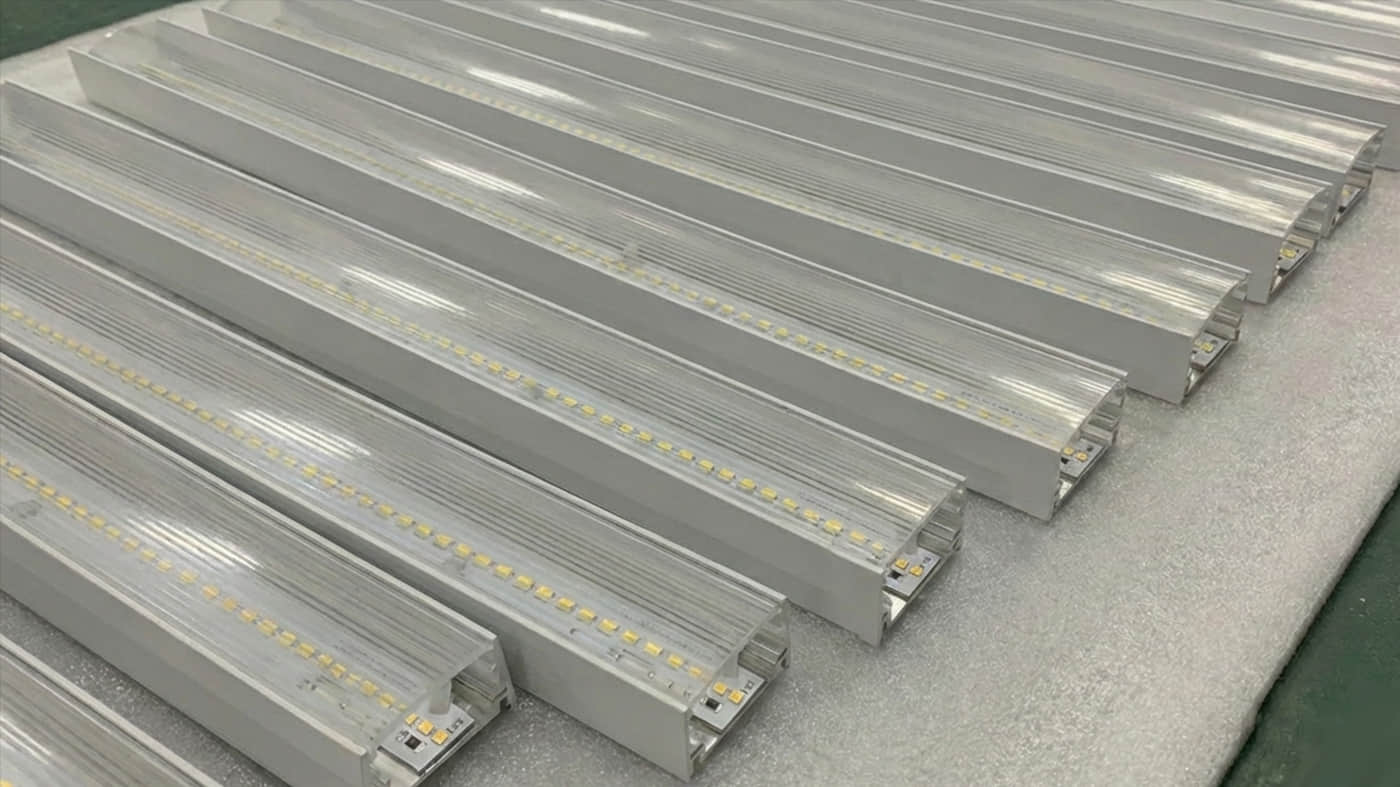

Our comprehensive range of extrusion linear lenses designed for various lighting applications and performance requirements.

ASEL AO features varying housing sizes and beams like 50x95° or 60x100°. We produce these extruded optics in any length required for your project.

Extruded linear lenses are versatile optical solutions suitable for a wide range of lighting applications that require seamless linear illumination, precise light control, and uniform distribution. For example, our Suspension Linear Profiles, Recessed Linear Profiles, and Surface Linear Profiles can be applied in common settings such as supermarket retail lighting, conference rooms, and office lighting. They can be installed singly or in multiple parallel or staggered rows suspended from the ceiling, creating a modern visual tension while delivering uniform, soft ambient lighting. Additionally, their competitive procurement cost ensures that your lighting project can be launched swiftly.

We also offer DIY Curved Modules and Custom Curved Profiles to meet your specific lighting needs. Leveraging the flexibility and seamless continuity of extrusion lenses, we can produce lens profiles with custom bending radii. Thanks to their excellent flexibility and infinite continuity, light can gracefully follow curved walls, wrap around columns, or precisely outline unique spatial contours.

From initial concept to final delivery, we provide comprehensive end-to-end solutions tailored to your specific requirements

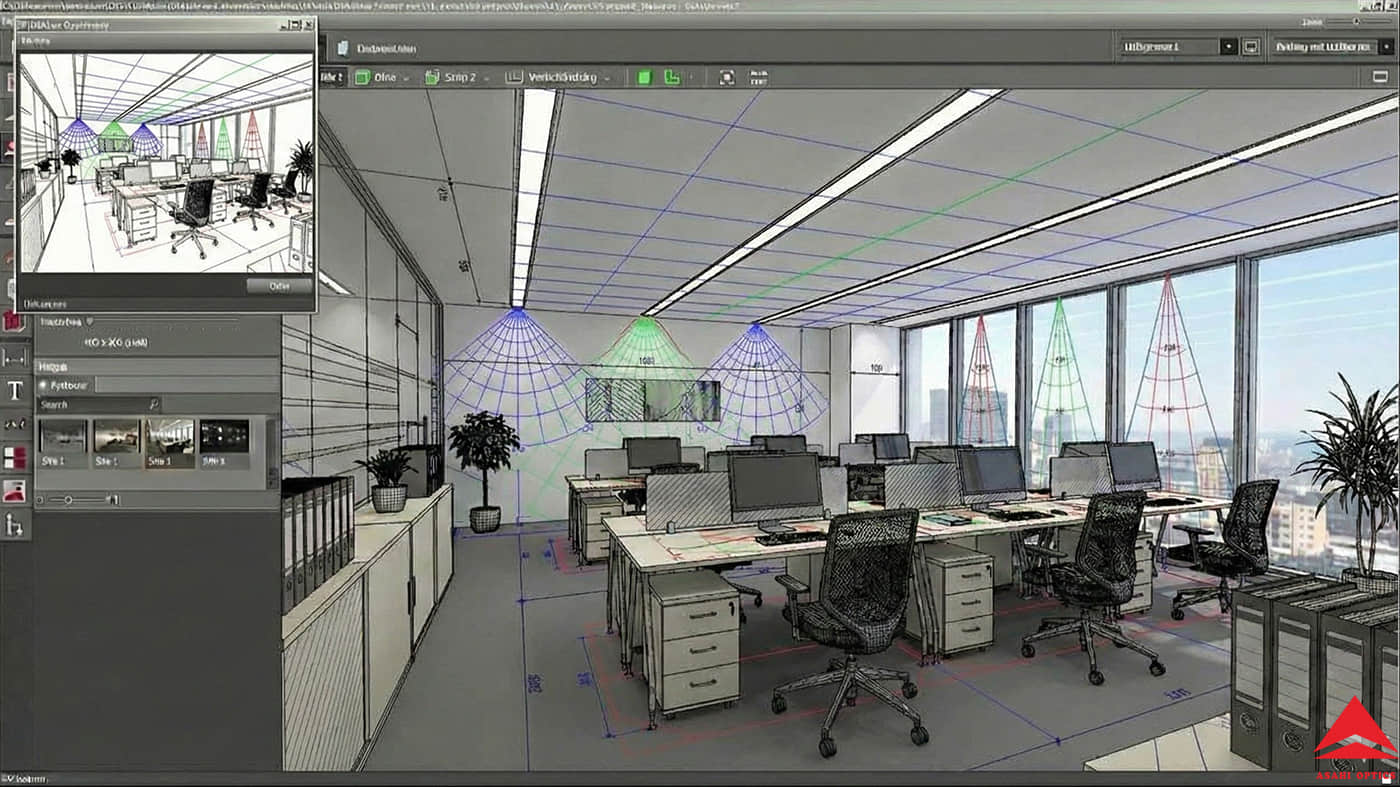

What is your lighting scenario? Social Area, Office Lighting, Retail Space, or Conference Room. The optical and stylistic design phase is critical. We can recommend suitable extrusion lenses based on the specific application, and also carry out structural design, optical simulation, thermal imaging, and DIALux simulation according to your requirements.

Excellent design begins with a thorough understanding of the needs. Our engineering team will work closely with you, leveraging deep industry experience and engineering expertise to ensure every design drawing serves as a reliable guide for efficient manufacturing, achieving a perfect balance between optical performance and production feasibility:

To ensure production capacity, we can select high‑grade, high‑hardness, and high‑wear‑resistance mold steels (such as H13, S136, etc.).

Our engineers use fluid‑flow simulation software to optimize the polymer flow path from the extruder to the final formed profile, ensuring balanced melt pressure and uniform flow velocity. This directly determines the dimensional stability and compactness of the product cross‑section.

After precisely aligning and integrating key components—including the extrusion die, calibrator, cooling tank, and puller unit—we conduct rigorous pre‑assembly and dimensional inspection to ensure all interfaces are flush and flow channels are smooth, laying the groundwork for a successful first trial.

The extruder barrel and die are equipped with up to 10 independent temperature zones, providing gradient‑based precise temperature control throughout the material's transition from "solid‑state → viscoelastic‑state → molten‑state." This ensures thorough plasticization and uniform melt consistency, laying the foundation for stable extrusion.

Through closed‑loop control with a high‑precision gear pump and melt pressure sensors, the polymer melt entering the die maintains extremely stable pressure and flow rate. This is the prerequisite for achieving constant cross‑sectional dimensions and accurate replication of optical surfaces.

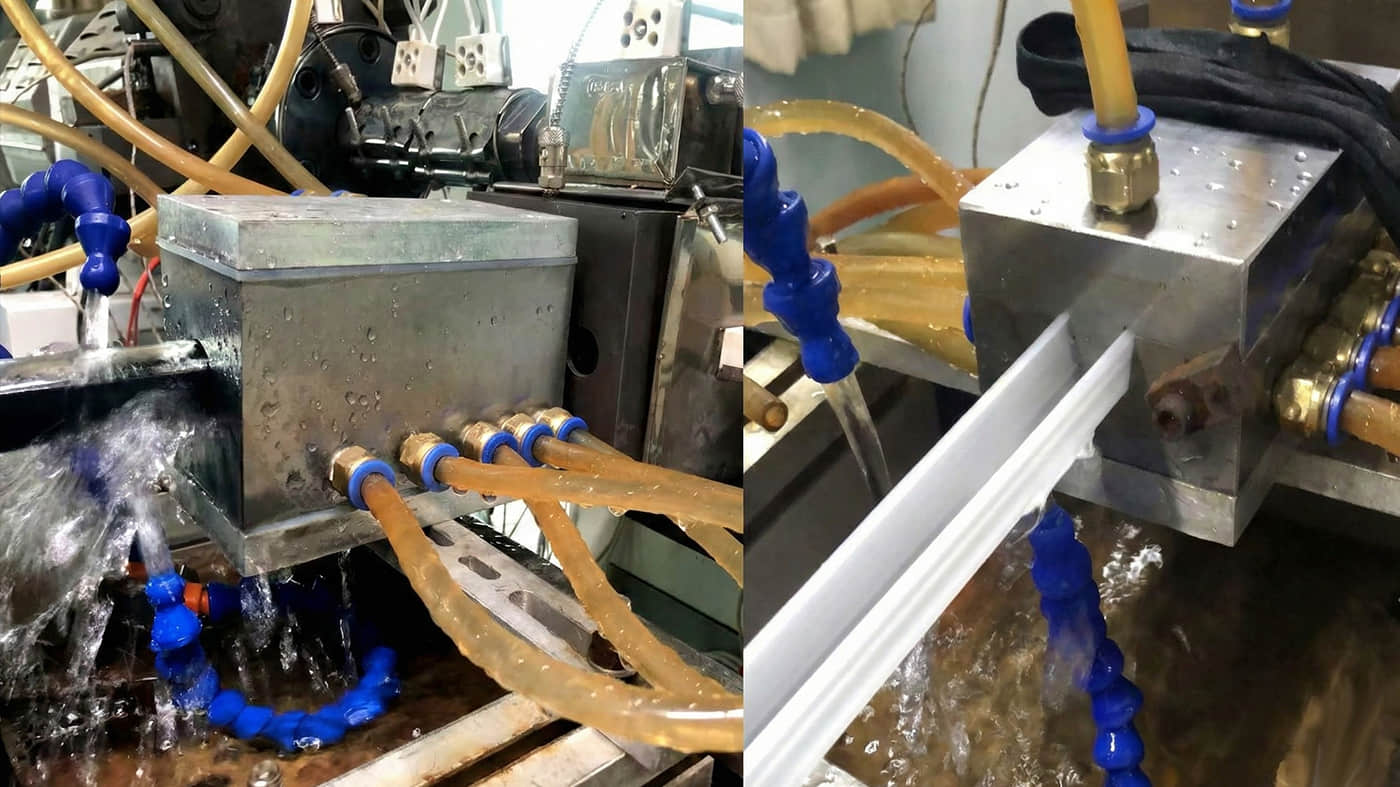

The hot molten parison extruded from the die immediately enters our core technology—the multi‑stage vacuum calibration cooling tank. Precisely controlled vacuum adhesion forces the softened material to fully conform to the optical surface of the calibration mold cavity. Coupled with segmented gradient water cooling, the product solidifies uniformly and gently from surface to core, minimizing internal stress and warpage to the greatest extent.

We not only provide lenses but can also serve as an extension of your supply chain, taking on responsibilities such as complex processing and pre‑assembly. This helps you streamline your production process, shorten time‑to‑market, and ensure high consistency across final product components.

For large‑volume, fixed‑length products, we employ servo‑controlled multi‑blade automatic cutting machines to ensure flat, perpendicular cut surfaces. For lenses requiring complex end‑face shapes (such as bevels, arcs, or special mounting features) or extremely high‑precision end‑face quality, we use CNC machining centers to guarantee perfect alignment with the luminaire structure.

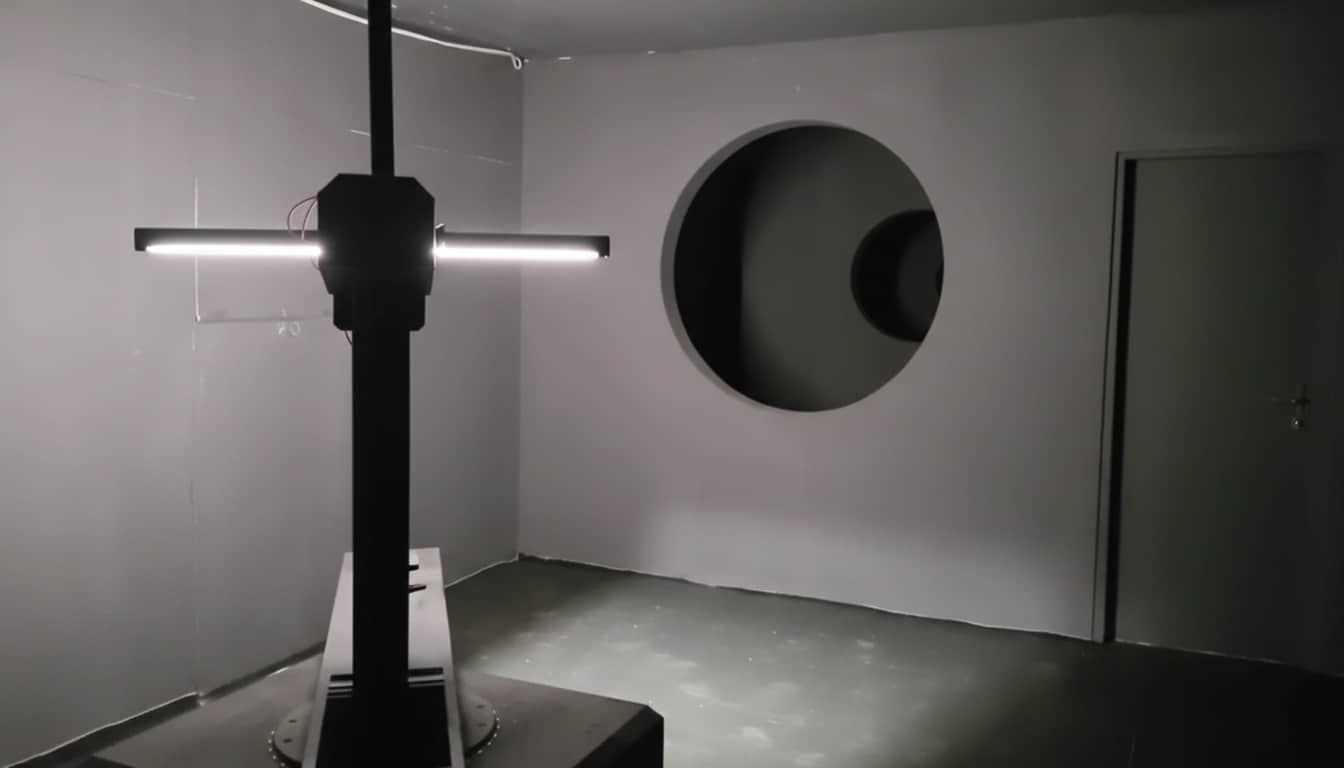

Our testing services strictly adhere to industry standards, including professional optical performance testing (photometric testing). The IES files we provide serve as authoritative references for your lighting design, glare calculations, and energy efficiency evaluations.

Our testing process ensures that what we deliver is not just an extruded optical lens that meets the drawing specifications, but a reliable optical component that withstands the test of time and environment. This fundamentally reduces your project risks and empowers your product to build a lasting reputation for quality in the market.

We have established strategic partnerships with leading global and regional logistics service providers, offering comprehensive sea, land, air, and multimodal transport solutions. Whether you require expedited air freight for urgent projects, cost‑optimized sea freight for large‑volume orders, or balanced speed‑to‑cost land transport via the China‑Europe Railway Express, we can plan the most competitive routing for you.

For precision optical surfaces, we employ anti‑static, scratch‑resistant stretch film, EPE foam, or custom‑cut foam for the primary protective layer. External packaging is reinforced using cardboard tubes, cartons, and pallets—all tailored to the shape and size of your order. If you prefer wooden crates for packaging, we support that option as well!

Contact our team for a personalized consultation and quote

Find answers to common questions about our extrusion linear lens technology and services

We primarily use optical-grade materials such as:

Material selection depends on your specific application requirements including optical performance, environmental conditions, and budget considerations.

Our minimum order quantities vary based on the complexity and customization level

We offer flexible solutions for both large-scale production and smaller development projects. Contact us to discuss your specific volume requirements.

Extrusion linear lenses offer several distinct advantages that make them ideal for modern lighting applications. Here are the key benefits:

| Advantage | Description | Benefit |

|---|---|---|

| Seamless Continuity | Continuous light distribution without dark spots or joints | Perfect for applications requiring uniform linear illumination |

| Optical Uniformity | Blends discrete LED points into continuous soft light band | Enhanced visual comfort and reduced glare |

| Design Flexibility | Custom cross-sectional profiles for specific light distributions | Tailored solutions for various lighting requirements |

| Cost Efficiency | Lower per-meter cost for long production runs | Economical for large-scale linear lighting projects |

| Glare Control | Precisely designed optical surfaces reduce direct brightness | Ideal for offices, schools, and healthcare environments |

| Simplified Integration | Seamless integration with LED boards and aluminum profiles | Streamlined assembly and improved structural integrity |

| Custom Lengths | Can be produced in virtually any continuous length | Eliminates the need for multiple segments and joints |

| Production Scalability | Efficient continuous manufacturing process | Rapid production for both small and large orders |

Lead times vary depending on project complexity:

For existing tooling and standard materials

Requiring new die development and prototyping

Involving multiple iterations and testing phases

We provide detailed project timelines during the quotation phase and maintain regular communication throughout the development process.

We specialize in producing high-quality LED linear profiles and linear lighting solutions. Our products are customizable to meet the specific needs of our clients.

Yes, we provide samples to help you evaluate the quality and suitability of our products for your projects. Please contact us to request a sample.

Asahi Optics welcomes your questions, inquires and feedback. Please use the form below or contact us at any of the addresses below. Our sales team will get back to you shortly.