In the competitive world of LED display technology, the quality of the backlight unit (BLU) determines the visual performance of the final product. For TV manufacturers, achieving perfect brightness uniformity without "hot spots" (mura) is the ultimate goal. This requires more than just a piece of plastic; it demands a high-precision TV backlight optical lens.

At Asahi Optics, we position ourselves as more than just a TV backlight lens manufacturer. We are an end-to-end solution provider, guiding our clients from the initial optical concept through precision mold fabrication to large-scale mass production.

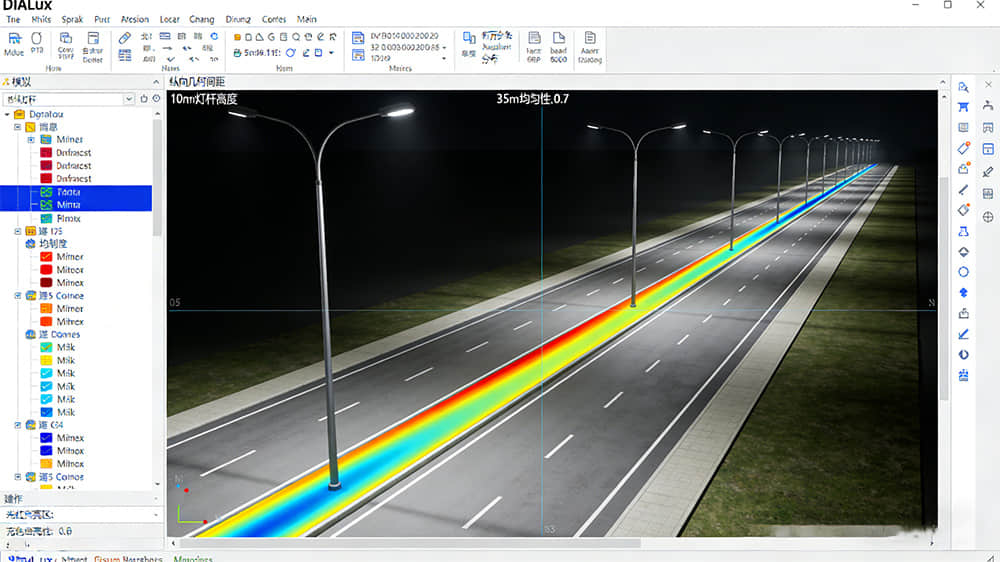

Optical Design: Solving Uniformity Challenges

The core of a high-quality Direct-Lit (D-LED) TV lies in its optical design. As a professional custom backlight optics supplier, our engineering team utilizes advanced optical simulation software to create free-form surface designs.

Our design process focuses on three critical performance metrics:

- Wide Beam Angle: We design lenses that expand the light beam angle (typically 150° to 170°) to cover larger areas with fewer LED chips, optimizing cost for our clients.

- OD Ratio Optimization: We optimize the Optical Distance (OD) to ensure the TV can remain slim while maintaining uniform light diffusion.

- Color Consistency: Our TV backlight lens design minimizes color shift (yellow rings), ensuring pure white light across the screen.

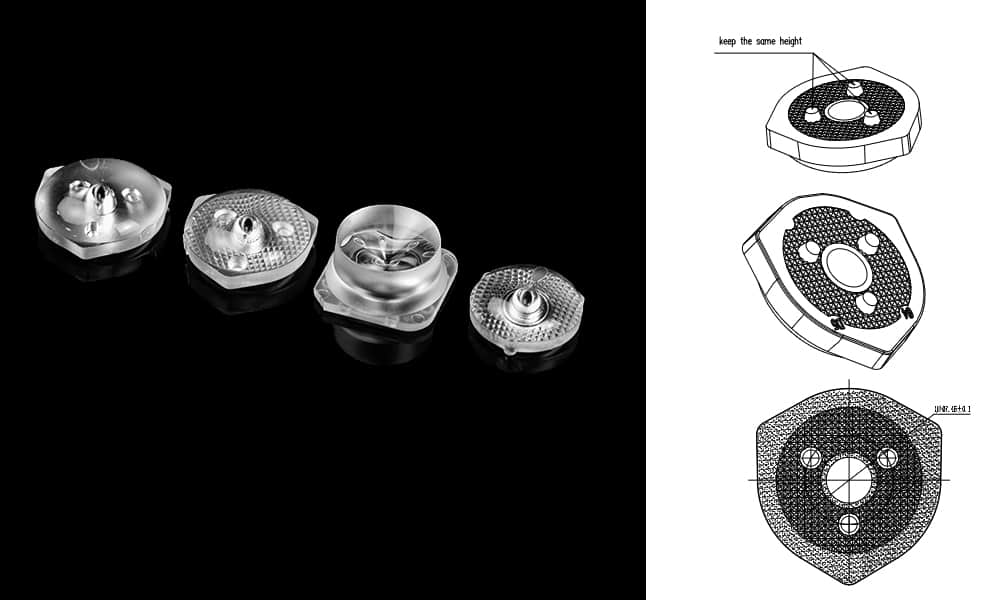

Independent Mold Development

The difference between a standard lens and a premium lens often comes down to the mold. Asahi Optics is a dedicated backlight lens mold manufacturer with in-house tooling capabilities.

We do not rely on third-party mold makers. By operating our own CNC machining centers and diamond turning machines, we achieve:

- Micron-Level Precision: Ensuring the physical lens surface matches the optical simulation 100%.

- Speed to Market: We can modify molds and produce T1 samples significantly faster than competitors who outsource tooling.

- Confidentiality: Your proprietary optical designs remain safe within our facility.

Mass Manufacturing & Material Selection

Transitioning from prototype to mass production requires robust manufacturing infrastructure. As a reliable TV backlight lens manufacturer, we utilize optical-grade PMMA materials (from top-tier suppliers like Mitsubishi and Sumitomo) to ensure light transmittance exceeds 92%.

Our injection molding workshop is equipped with high-tonnage, fully automated electric injection machines. These machines ensure stable pressure and temperature control, which is crucial for maintaining the dimensional stability of every TV backlight optical lens we produce, whether the order is for 10,000 pieces or 1 million pieces.

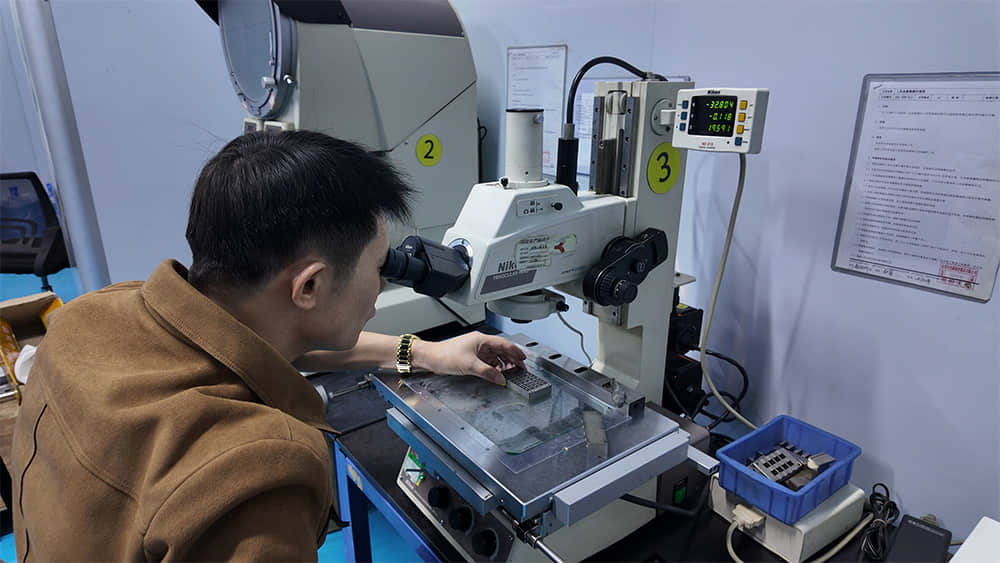

Rigorous Quality Assurance (QA) & Detection Processes

In the automotive and display industries, a single defect can ruin a brand's reputation. Asahi Optics implements a strict quality control workflow that covers every stage of production:

1. Optical Performance Testing

We use Goniophotometers and Integrating Spheres to verify the light distribution curve (LDC) and luminous flux, ensuring the TV backlight lens meets the specific beam angle requirements.

2. Dimensional Inspection

Using CMM (Coordinate Measuring Machines) and non-contact vision measuring systems, we verify that the lens feet and height meet strict tolerance levels for automated SMT mounting.

3. Surface Quality (AOI)

To prevent cosmetic defects, we employ Automated Optical Inspection (AOI) systems. This technology detects:

- Black dots or impurities inside the lens.

- Scratches or flow marks on the surface.

- Flash or burrs on the injection gate.

Partner with Asahi Optics

Whether you are developing a new Mini-LED project or looking for a cost-effective replacement for standard OD lenses, Asahi Optics is your trusted partner. From being a backlight lens mold manufacturer to a full-scale production hub, we deliver precision, quality, and scalability.

Contact us today to discuss your custom optical requirements and request a quote for your next project.