When a municipality invests millions in upgrading to LED street lighting, they aren't just buying "bulbs"; they are investing in a sophisticated, integrated electronic system.

A modern LED roadway luminaire is an engineering marvel composed of five critical subsystems: the Housing, the Thermal Management System, the Driver, the Light Source, and the Optical Lens. While the LED chip generates the light, it is the Optical Lens that determines whether that light becomes a safety asset or a source of blinding pollution.

In this comprehensive guide, Asahi Optics deconstructs the anatomy of a high-performance LED street light, analyzing the function of every component, and explaining why the optical lens is the "Director" that defines the fixture's ultimate value.

The Anatomy of a Street Light

To understand the lens, we must first understand the ecosystem it lives in. If any of these four supporting components fail, the lens cannot perform its job.

1. Housing & Structural Components

-

Composition: Typically High-Pressure Die-Cast Aluminum (ADC12).

-

Function: Provides mechanical protection (IK Rating) and corrosion resistance.

-

Critical Engineering: For coastal or industrial areas, the housing needs 500+ hours of Salt Spray Testing. If the housing corrodes, the seal breaks, water enters, and the lens fogs up.

2. The LED Driver

-

Composition: A complex AC/DC power supply with capacitors, transformers, and surge protection devices (SPD).

-

Function: Converts unstable mains voltage into constant current for the LEDs.

-

Critical Engineering: In outdoor lighting, lightning strikes are a real threat. A robust driver must have 10kV or 20kV Surge Protection. Without this, the entire "heart" stops beating during a storm.

3. Thermal Management (Heatsink)

-

Composition: Aluminum fins (integrated into the housing) or copper heat pipes.

-

Function: Dissipates the intense heat generated at the LED Junction ($T_j$).

-

Critical Engineering: This is directly linked to the lens. If the heatsink fails to keep the PCB temperature below 85°C, the Optical Lens (especially if made of cheap material) can suffer from carbonization or yellowing, causing light output to drop by 30% in a year.

-

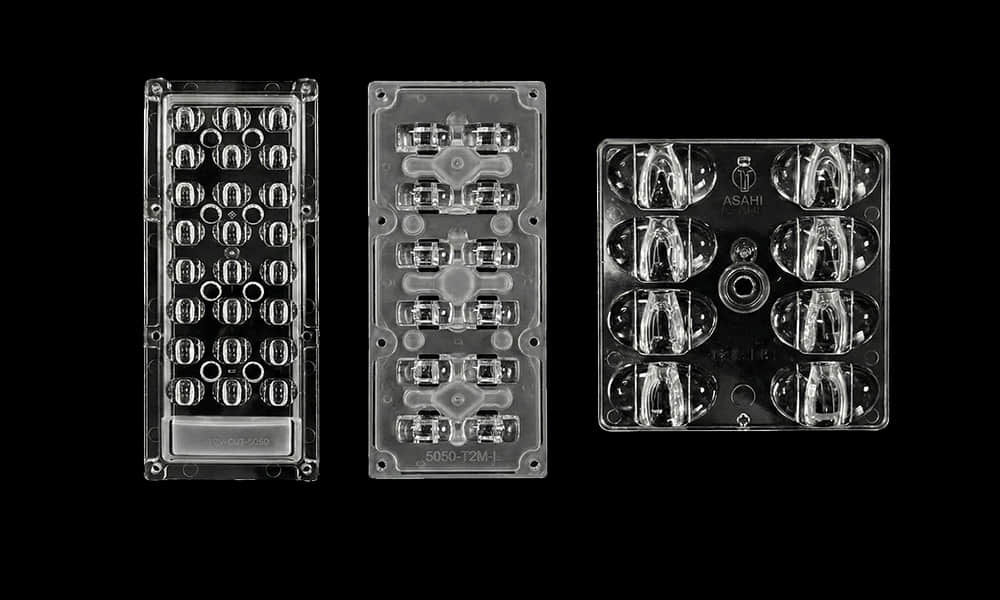

Asahi Innovation: Our 72 LEDs Multi-Module Lens features a centrally reserved 40x40mm groove, specifically designed to align with the heat dissipation ribs, maximizing airflow efficiency.

-

4. LED Package (SMD)

-

Composition: Surface Mount Diodes, typically 3030 (Low power) or 5050 (High power).

-

Function: Converts electricity into photons.

-

The Problem: A raw LED chip emits light in a Lambertian distribution (a 120° wide cone). If you put a raw LED over a road, 50% of the light hits the grass, and the area directly under the pole is too bright (Hot Spot).

This leads us to the most critical element.

Why the Optical Lens is the Most Critical Element

If the LED is the "Engine" that produces power, the Optical Lens is the "Transmission" that applies that power to the road.

Without a high-precision lens, an LED street light is essentially a floodlight—inefficient and dangerous. The lens dictates three core value metrics: Uniformity, Safety (Glare Control), and Application Efficiency.

1. Controlling the "Photon Budget" (System Efficacy)

Light is expensive. Every lumen wasted on the sky or a neighbor's backyard reduces the system's efficiency. Asahi Optics utilizes TIR (Total Internal Reflection) technology. Our lenses capture >90% of the photons emitted by the LED and redirect them entirely to the target surface.

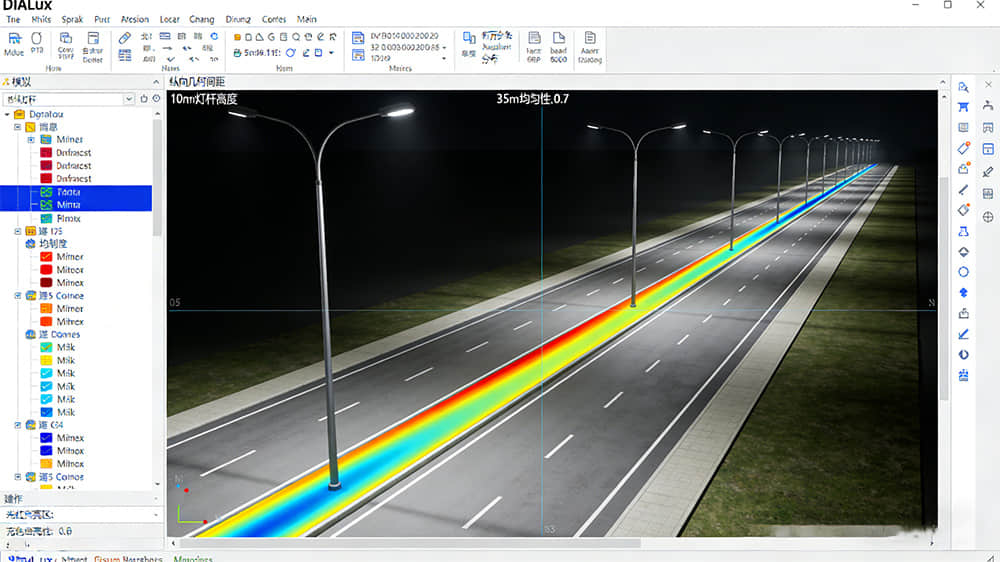

On highways, poles are expensive. Engineers want to space them as far apart as possible. Our High Quality PC Lens 5050LED T2M For Long Pole Distance is engineered for this exact economic need. By using a large 173mm optical surface to collimate the light from high-power 5050 LEDs, we stretch the beam pattern longitudinally.

-

The Result: You can reduce the number of poles per kilometer by 20%, saving massive infrastructure costs.

2. The Battle Against Light Pollution (Cutoff Design)

In residential zones, "light trespass" is a major complaint. Residents do not want street lights shining into their bedrooms. Standard lenses spill light backwards. Asahi Optics solves this with Backlight Shielding geometry embedded in the mold.

-

The Solution: 2X4 Arrays 5050LED T2 Excellent Cutoff Street Light Lens.

-

The Engineering: This 50x50mm module features a strict "Cutoff" line. It ensures that light is pushed forward onto the street (Type II distribution) but sharply cut off behind the pole, protecting the privacy of residents and complying with Dark Sky regulations.

3. Integrated Protection (IP66 Waterproofing)

In traditional street lights, the lens is covered by a flat glass sheet. This glass sheet absorbs ~10% of the light. Modern optical engineering removes this barrier.

-

The Innovation: IP66 Street Lighting 3x8 Lens 5050LED T2M-Cutoff.

-

How it works: We integrate a silicone gasket channel directly into the lens perimeter. The lens itself acts as the protective cover.

-

The Benefit: By removing the glass, you gain +10% System Lumen Output. The lens is made from high-grade, UV-stabilized PC (Polycarbonate), which is impact-resistant (IK08) and weatherproof, simplifying the entire fixture assembly.

Deep Dive into Optical Materials & Precision

The performance of the lens is not just about shape; it is about Material Science and Mold Precision.

Material: PC vs. PMMA

For street lighting, Polycarbonate (PC) is the industry standard for a reason.

-

Thermal Resistance: PC can withstand temperatures up to 125°C (compared to 90°C for PMMA). This is crucial because the lens sits millimeters away from the hot LED chip.

-

Impact Resistance: Street lights face hail, vandalism, and bird strikes. PC is virtually unbreakable.

-

Asahi Standard: All our outdoor lenses, including the Street And Area Lighting Lens, utilize UV-stabilized optical-grade PC to prevent yellowing for 5-10 years.

Conclusion: The Lens Defines the Light

Whether you need to maximize pole spacing on a highway with our Long Pole Distance Lens, or protect residential privacy with our Cutoff Optics, the lens is the single most critical element in your specification sheet.

Don't compromise on your optics. Contact Asahi Optics today. From standard IP66 Multi-modules to custom optical designs, we provide the precision engineering that modern cities demand.