In modern LED optical engineering, 36in1 lenses have become a key component in achieving high-performance lighting for outdoor and industrial applications. Their internal optical structure, lens geometry, and light distribution patterns can vary; these lenses' optical designs and lighting performance vary depending on their intended application.

This article explores the key differences between two common 36in1 lenses—one with a diameter of 180mm and the other with a diameter of 253.5mm—and how their customized optical lens structures support different lighting objectives.

1. Design Philosophy

The first 36in1 lens is engineered with maximum luminous output as its priority. It’s tailored for environments such as sports arenas or high-bay industrial spaces, where light intensity and uniformity are critical.

In contrast, the second type — the Type II Medium (T2M) cutoff 36in1 lens — is designed around optical precision and light control, focusing on directing light precisely along streets and pedestrian zones while minimizing glare and wasted spill light.

This difference in design philosophy determines every detail that follows — from lens diameter to optical cell arrangement, beam distribution, and material composition.

2. Structural Comparison

The 180mm 36in1 lens has a relatively compact diameter. Its rounded light-guiding particles allow for a variety of angles, making it ideal for evenly projecting a beam across large, open areas like sports fields or factory halls.

On the other hand, the 250mm 36in1 lens measures approximately 250 x 120 mm. This slender structure aligns with the linear nature of the road, helping to shape the light into a horizontal, elliptical pattern that extends further down the street.

This geometric difference alone is enough to clarify the design intent: one aims for even surround illumination, while the other focuses on directional, linear beam projection.

3. Optical Cell Arrangement and Light Guide Pattern

Although both are “36in1,” their optical cell arrangements (the distribution of the 36 micro-lenses) are completely different:

In the 180mm 36in1 lens, the 36 optical cells are organized in a concentric or grid-like matrix, optimized for multi-directional reflection and refraction. Each cell operates independently to deliver powerful, overlapping beams that merge into a broad, seamless illumination zone. The internal light-guiding surfaces are polished to minimize light scattering and maximize luminous efficiency.

In contrast, the 250mm 36in1 lens uses a staggered linear arrangement of its 36 optical cells, with each optical unit slightly tilted or offset. This asymmetrical configuration enables a Type II Medium beam shape — a butterfly-like pattern that throws light further along the road while keeping the roadside area softly lit. The light guide facets here are more complex, designed to “cut off” stray light and create a crisp, glare-free edge.

This variation in micro-lens orientation and light-guiding geometry is what truly defines their beam behavior and application suitability.

4. Material and Optical Efficiency Considerations

Both lenses utilize high-transmittance polycarbonate (PC) materials, chosen for their durability, impact resistance, and weather stability.

However, the surface micro-texturing and coating techniques differ according to use case:

The stadium version prioritizes optical clarity and high efficiency, ensuring that more than 90% of emitted light passes through the lens with minimal diffusion.This enables brilliant illumination in tall-mounting applications without significant light loss.

The streetlight version, however, uses a more diffused surface micro-texture to control brightness and achieve a smoother light gradient. While transmittance remains high, the slight diffusion contributes to reduced glare and improved visual comfort — critical for urban lighting.

5. Beam Pattern and Lighting Application

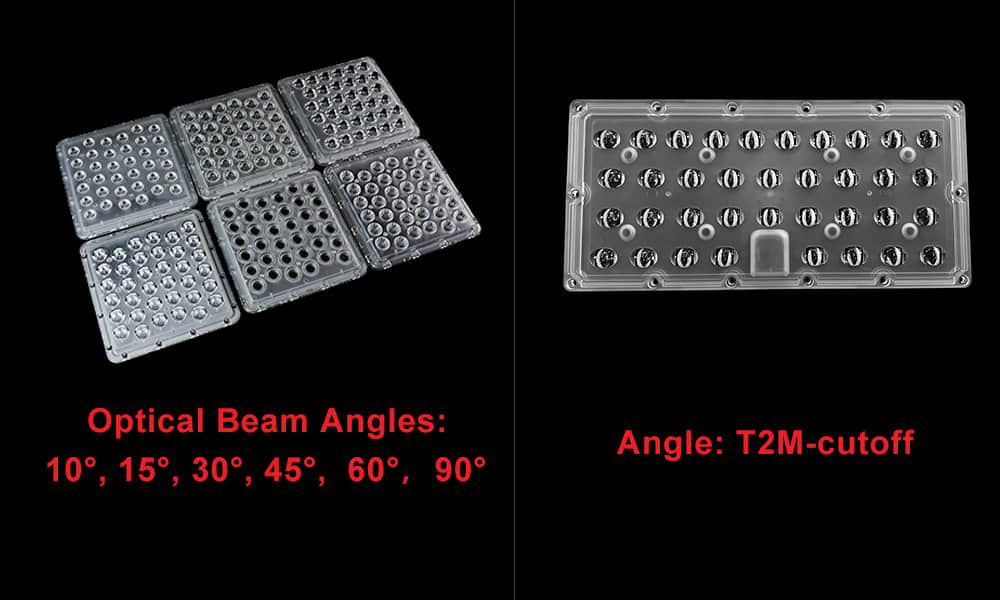

The 180mm type 36in1 lens provides multiple beam angle options — from narrow spot beams to wide flood configurations.

This allows lighting designers to customize coverage depending on the height of the fixture and the scale of the area to be illuminated. It’s the preferred choice for sports fields, construction sites, ports, and industrial complexes where light must reach both horizontally and vertically across long distances.

The street lighting lens, by contrast, employs a Type II Medium (T2M) light distribution with a cutoff beam edge.

This pattern ensures light is directed toward the road surface without spilling onto adjacent zones like sidewalks or residential windows. Its rectangular structure fits seamlessly into modern street light housings or area luminaires, ensuring compliance with international lighting standards and city-level optical uniformity requirements.

6. Custom Optical Lens Development Potential

| Aspect | 180mm 36in1 Lens | 250mm 36in1 Lens |

|---|---|---|

| Optical Cell Arrangement | 6x6 layout | Staggered asymmetric layout |

| Light Distribution | Narrow to wide beams (10°–90° options) | Type II Medium cutoff distribution |

| Beam Focus | Power and intensity | Precision and visual comfort |

| Main Application | Stadiums, ports, industrial zones | Roads, urban areas, pedestrian routes |

Both embody the core principles of Asahi optical design—achieving the perfect balance between performance, control, and durability. If you need customized content, you can contact the Asahi team at any time