In the optical industry, whether it is LED Lenses, mobile phone lenses, automotive lighting optical components, or professional lighting optical assemblies, the core manufacturing process is inseparable from "molds." Especially for products like the LED optical lenses that we at Asahi Optics specialize in, the production process places extremely high demands on mold standards, processing accuracy, and interchangeability. Therefore, understanding the mold standard system holds significant value for both optical design and optical production.

The following content introduces the "Four Major Standard Systems for Injection Molds," widely used in the optical industry and particularly common in the manufacturing of LED lens injection molds.

Four Major Standards for Injection Molds

The so-called "Four Major Standards for Optical Lens Molds" or "Four Major Standard Systems for Injection Molds" refer to four globally recognized and widely adopted sets of top-tier commercially available mold standard component systems. These standards not only influence traditional industrial molds but also have a profound impact on the design of LED optical lens injection molds (LED Lens Mold) within our industry.

D-M-E (USA)

Affiliated Company: D-M-E Company (now part of the UK-based Siron Group)

Key Features: The oldest and most globally influential standard. D-M-E has almost become synonymous with mold standard components. Its standard system is exceptionally comprehensive, covering everything from plates, mold bases, to cooling and ejection parts. In the optical industry, many LED lens injection molds, automotive lighting molds, and precision optical component molds adopt the D-M-E standard due to its stability, reliability, and mature global supply chain.

Application Scope: The mainstream standard for molds exported from North America, also commonly used in the development of molds for high-end optical components.

HASCO (Germany)

Affiliated Company: HASCO Hasenclever GmbH

Key Features: Renowned for European precision manufacturing, with high modularity and excellent interchangeability. HASCO places particular emphasis on cooling system design, which is crucial for the molding quality of optical lenses, as optical materials (such as PMMA and PC) are highly sensitive to temperature control.

Application Scope: Widely used in European precision machinery, automotive lighting, and high-end optical lens mold manufacturing.

MISUMI (Japan)

Affiliated Company: MISUMI Group

Key Features: Renowned for standardized and automated components, with comprehensive 3D data and fast delivery times, making it ideal for companies requiring rapid design and development of optical lens molds. Many LED Lens factories and optical component manufacturers in Asia heavily rely on MISUMI's standard component system.

Application Scope: The mainstream choice for Japanese, Korean enterprises, and numerous optical injection molding factories across Asia.

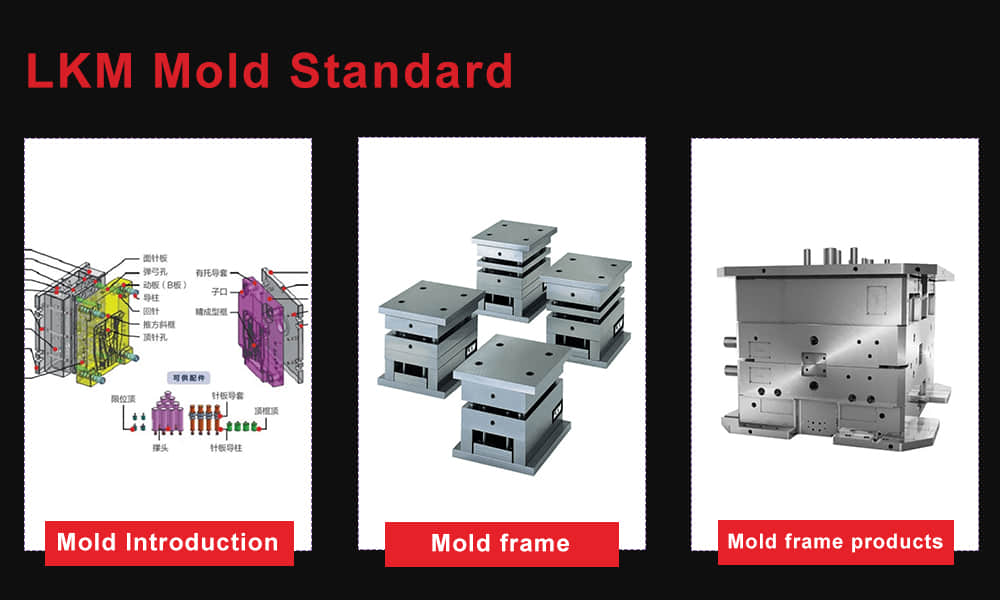

LKM (China)

Affiliated Company: LKM Group

Key Features: The world's largest mold base manufacturer. LKM is known for its high cost-effectiveness and fast delivery, making it one of the most commonly used mold standards in China's optical industry. Many LED lens factories and automotive lighting optical component factories utilize LKM mold bases for mold development.

Application Scope: The dominant standard in mainland China, Taiwan, Hong Kong, and the optical industries of Southeast Asia.

Relationship with Optical Lens Manufacturing

Although the four major systems mentioned above are essentially "mold standards universal to all industries," their importance is particularly prominent in the injection molds for LED lenses, optical diffusers, and automotive lighting optical components.

This is because optical products must meet:

- Micrometer-level accuracy

- High surface quality (optical mirror finish)

- Extremely low defect rate

- Strict cooling and demolding control

Therefore, when constructing molds, optical enterprises prioritize adopting established standards such as D-M-E, HASCO, MISUMI, and LKM to ensure production stability and optical performance.

How to Select Optical Lens Mold Standards

Consider Customer Markets:

- Molds for optical components exported to North America → Commonly use D-M-E

- Lenses exported to Europe → Commonly use HASCO

- Japanese clients or high-precision lenses → Commonly use MISUMI

- Mass production of LED lenses or optical covers → LKM offers the best cost-effectiveness

Consider Precision Requirements:

- High-precision optical components → HASCO, D-M-E

- Large-volume LED lenses → MISUMI, LKM

Consider Production Cycle and Costs:

- Short lead time and rapid development → MISUMI

- Cost-friendly solutions → LKM

Consider Supply Chain:

- Procuring from nearby suppliers is more efficient and reduces the risk of production downtime for optical factories.

| Standard System | Primary Origin | Core Characteristics | Primary Market |

|---|---|---|---|

| D-M-E | USA | Long history, global benchmark | North America, high-end optical molds |

| HASCO | Germany | Precision reliability, modular design | Europe, precision optics industry |

| MISUMI | Japan | Extensive 3D model library, fast delivery | Asian optical component manufacturers |

| LKM | China | High cost-effectiveness, rapid supply | China market, LED lens factories (mainstream choice) |

Mold Standards Form the Foundational Core of Optical Product Quality

When we discuss the four major mold standards, we are not merely talking about the traditional mold industry, but about the cornerstone engineering of the entire optical supply chain. High-quality LED optical lenses are inseparable from high-standard mold systems.

As an LED optical lens manufacturer, the mold systems we use in producing LED lenses, optical lenses, linear optical elements, and automotive lighting lens optical components are precisely based on these globally recognized standards.

For Example:

- LED Lens Molds (Street Lighting Lenses)

- Optical Structural Component Molds (Automotive Lighting Optics)

- Extrusion Linear Lens Molds (Extrusion linear Lens)

All of these rely on precise mold standard systems.