In the medical field, lighting is not just about brightness; it is about precision, safety, and visual comfort. Whether in a large operating theater or a dental clinic, the optical component is the heart of the lighting system.

As a dedicated medical light lens manufacturer, we understand that different medical procedures require vastly different optical behaviors. We provide high-performance solutions that bridge the gap between Surgical Lighting Optics and Dental Lights Optics, ensuring doctors see clearly and patients remain safe.

Surgical Lighting Optics: Mastering Shadow Control

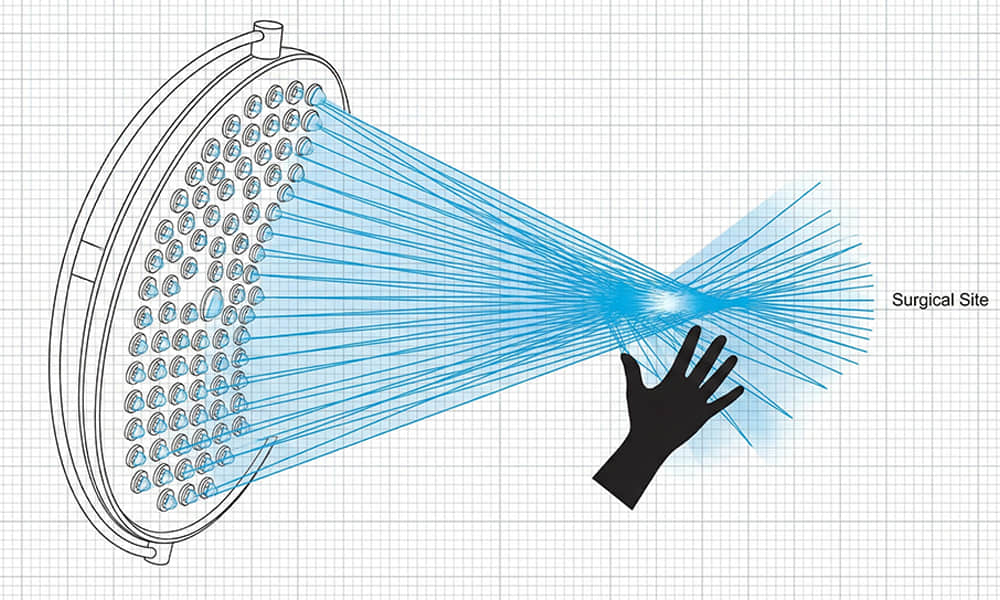

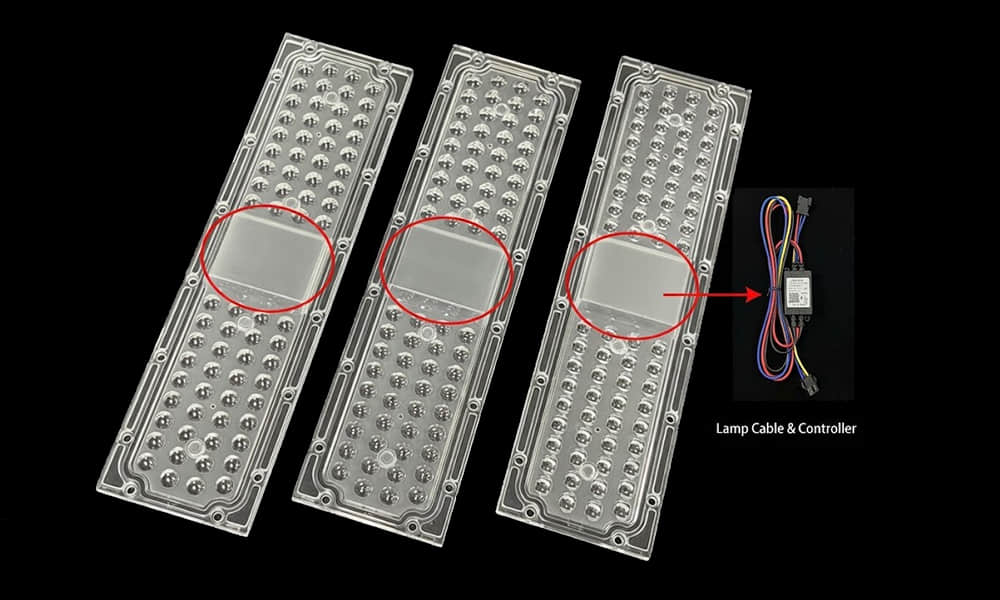

Modern operating lights have moved away from single, large reflectors to multi-LED matrix systems. At the core of this evolution is the surgical lighting single lens.

In high-stakes surgery, the primary challenge is "Shadow Dilution." The surgeon's head, hands, and instruments constantly obstruct the light path.

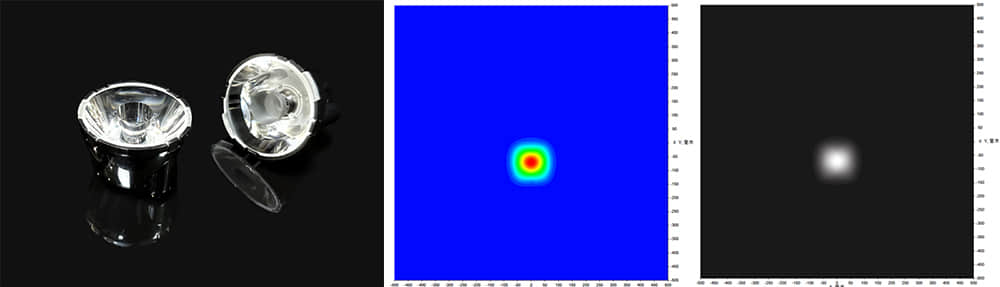

The Single Lens Advantage: By using individual collimating lenses for each LED, we create a system where hundreds of light beams overlap at the surgical site. Even if 50% of the light source is blocked, the remaining surgical lighting single lenses ensure the cavity remains illuminated without hard shadows.

Deep Cavity Penetration: Our optics are designed to focus light into deep, narrow incisions, maintaining high intensity (Lux) at the bottom of the wound, not just the surface.

Dental Lights Optics: Precision Pattern Definition

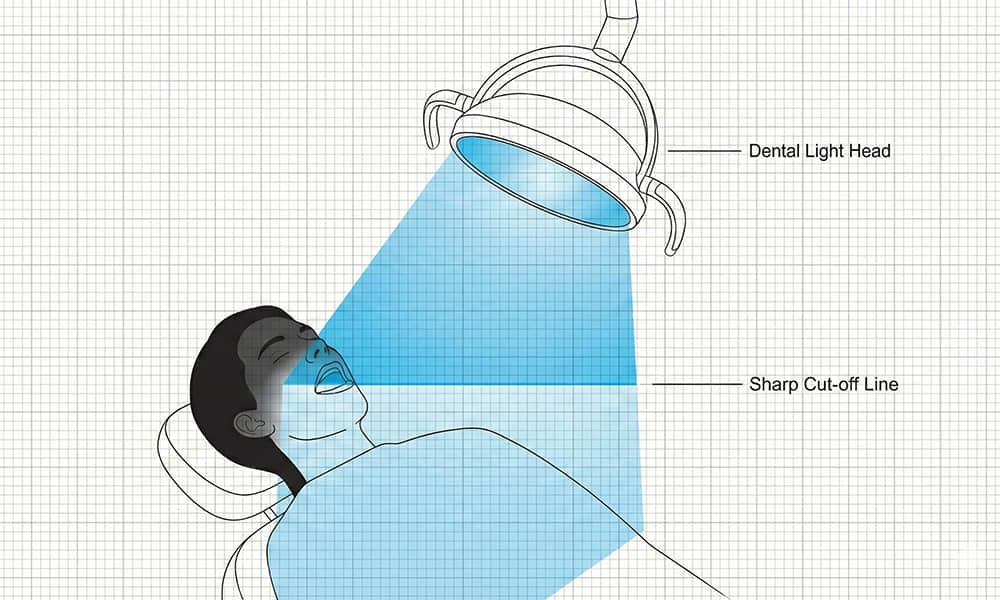

While surgical lights focus on power and shadow dilution, Dental Lights Optics present a different challenge: Geometry and Comfort.

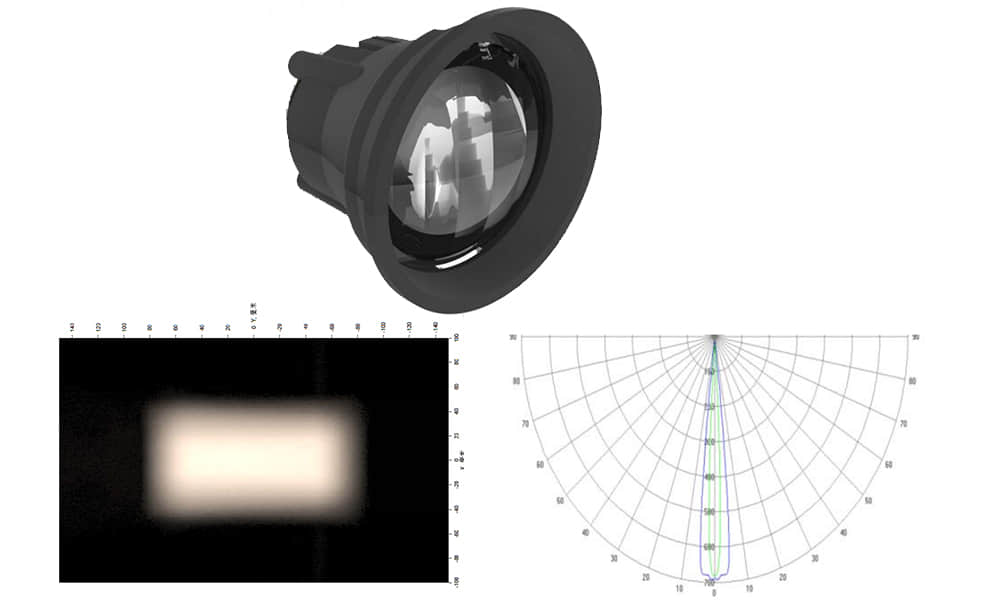

Dental lighting requires a specific "Rectangular Pattern" that illuminates the oral cavity perfectly without blinding the patient.

Sharp Cut-off Line: Our dental optical lenses are engineered with complex free-form surfaces to create a sharp "cut-off." This ensures strong light on the patient's teeth but keeps the light completely out of the patient's eyes.

Uniformity: We prioritize high uniformity within the light spot to prevent eye fatigue for the dentist, who must focus on the oral cavity for hours.

Why Partner with a Specialized Manufacturer?

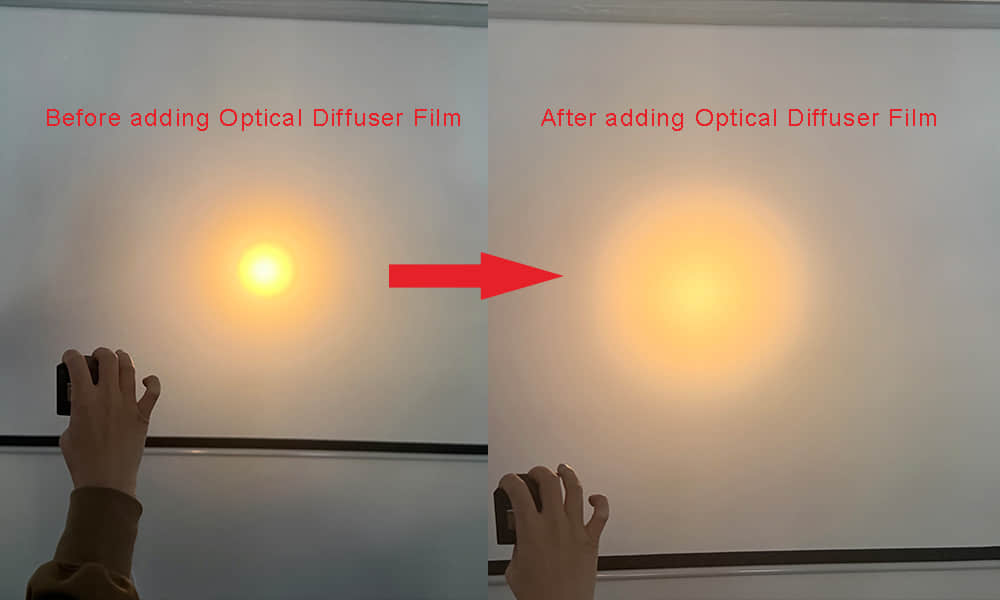

Designing for medical applications requires more than just standard injection molding. It requires a deep understanding of optical physics and material science.

Material Purity: We use medical-grade PMMA and PC materials that offer high transmittance and resistance to UV radiation and sterilization chemicals.

Color Accuracy (High CRI): Both surgical and dental procedures rely on tissue color diagnosis. Our lenses are optically neutral, ensuring the High CRI of your LED source is preserved (R9 > 90), allowing for accurate identification of inflammation or blood vessels.

Custom Medical Light Lens Services: In addition to surgical and dental lighting applications, we can also provide comprehensive simulation and mold manufacturing services tailored to your specific application scenario, regardless of how complex the lighting conditions may be.

Conclusion

From the intricate requirements of a dental check-up to the critical demands of open surgery, the right lens makes the difference. Trust a professional medical light lens manufacturer to deliver the optical precision your medical devices deserve.

Looking for a custom solution? Contact us to discuss your specific requirements for surgical or dental optical components.