1. Micro-Structure Design & Beam Logic

In the realm of high-end commercial and architectural lighting, the difference between a good fixture and a masterpiece often lies in the quality of the light beam itself. Asahi Optics is proud to introduce our latest breakthrough in photon management: Micro-Structure Optical Diffusion Film.

This is not a simple frosted sheet or a sandblasted consumable. It is a precision-engineered optical component designed to give lighting engineers absolute control over beam shaping, uniformity, and color mixing.

The Physics of Micro-Structure Diffusion

Traditional diffusion methods rely on random surface roughness to scatter light. While cheap, this approach is uncontrolled and inefficient. Asahi’s diffusion film adopts a calculated Micro-Structure Design.

Imagine millions of microscopic lenses or prisms arranged on the surface of the film. When a light beam passes through these structures, the light is not merely blocked or scattered; it is redistributed. The micro-structures manipulate the trajectory of each photon, expanding the beam angle in a controlled manner.

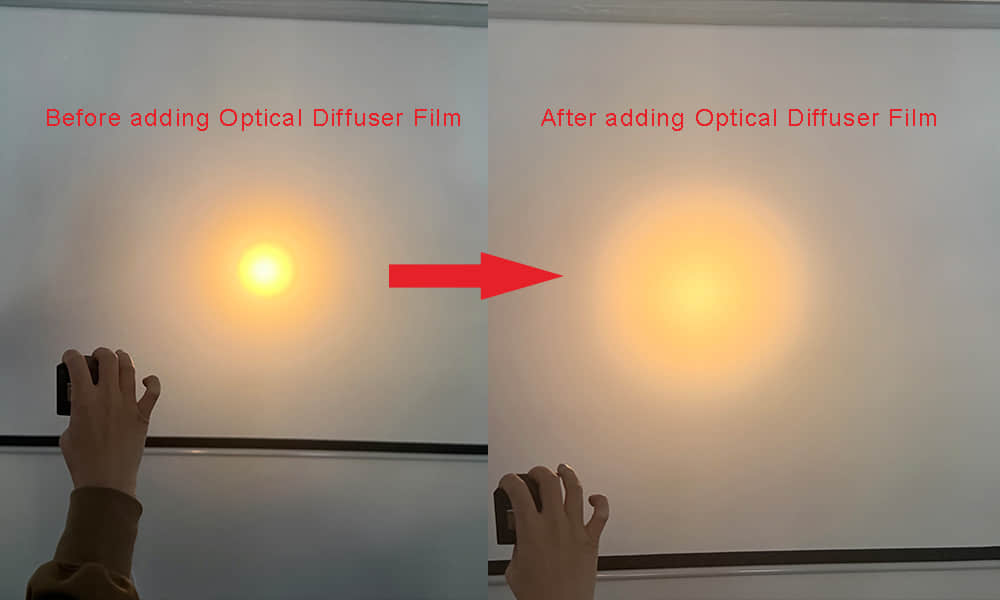

Physics dictates that when you spread a beam, the Center Beam Candlepower (CBCP)—or peak intensity—will drop. In exchange for this drop in peak intensity, you gain a massive increase in Field Uniformity. The film effectively takes the excess energy from the hot spot (the center) and pushes it toward the spill light (the edges), creating a soft, luxurious gradient that feels comfortable to the human eye.

Specific Example: Optimizing a 10° Lens

One of the most persistent headaches in LED lighting—especially with COB (Chip on Board) sources—is the Yellow Ring or Color-over-Angle (CoA) phenomenon. This occurs because the blue light and yellow phosphor emission paths do not perfectly overlap at wide angles, resulting in a beam that is blue in the center and distinctively yellow at the edges.

Standard wide-angle lenses often fail to correct this. However, pairing a Small-Angle Lens (≤10°) with Diffusion Film provides the ultimate solution. The final output eliminates all traces of yellow rings, dark spots, or irregular "donut" shapes. You get a perfectly mixed, soft-edged beam that looks superior to what a standard 36° or 60° lens can produce on its own.

Why is this combination superior to a native wide lens?

-

Source Purity: A narrow lens (e.g., 10°) is extremely efficient at collimating light. It captures the raw output before the colors separate significantly.

-

Active Mixing: When this tight, collimated beam hits our diffusion film, the micro-structures act as a blender. They mix the blue and yellow wavelengths aggressively before projecting the light out.

Unique Calculation Method for Beam Angle

Because our film acts as a modifier rather than a primary optic, defining the angle requires a specific calculation method. The angle labeled on our film (e.g., 5°, 10°) represents its diffusion capacity, not the final output angle.

To predict the Actual Beam Angle (θ_final) of your fixture, engineers should use the Root Sum Square (RSS) formula. This formula accounts for the vector addition of the lens angle and the diffusion angle.

Calculation Example:

Let's say you are designing a wall washer and want to slightly soften a sharp beam.

-

Primary Optic: You select an Asahi 10° Narrow Spot Lens.

-

Diffusion Film: You choose our 5° Diffusion Film.

Applying the formula: θ_final ≈ √(10² + 5²) ≈ 11.18°

Engineering Interpretation:

The math tells us that the beam will not simply widen to 15° (10+5). Instead, it expands to approximately 11-12°. This slight expansion signifies that the film is primarily working to smooth the edges and homogenize the flux, rather than drastically changing the field of view. This predictability allows you to simulate lighting effects accurately during the R&D phase.

2. Performance & Installation

Selecting the right diffusion film is not just about the angle; the physical thickness of the material plays a pivotal role in the mechanical stability and optical efficiency of the final fixture. Asahi Optics provides different thicknesses to adapt to diverse luminaire designs.

Thin Film (e.g., 0.175mm): The Efficiency Choice

For most compact indoor fixtures like downlights and track lights, our standard 0.175mm Thin Film is the optimal choice.

-

Higher Transmission: The thinner profile absorbs less light, resulting in higher overall system efficacy (lm/W).

-

Flexibility: Its pliability makes it easy to insert into curved slots or tight bezel rings without cracking.

Thick Film: Structural Integrity for Large Fixtures

For larger applications—such as high-power floodlights, wall washers, or industrial high bays—a thin film may risk sagging or warping. In these scenarios, we provide Thicker Gauge Films.

-

Anti-Sagging: Added rigidity allows the film to span wider distances without collapsing.

-

Durability: Offers better resistance to vibration and stress, ensuring optical alignment remains constant.

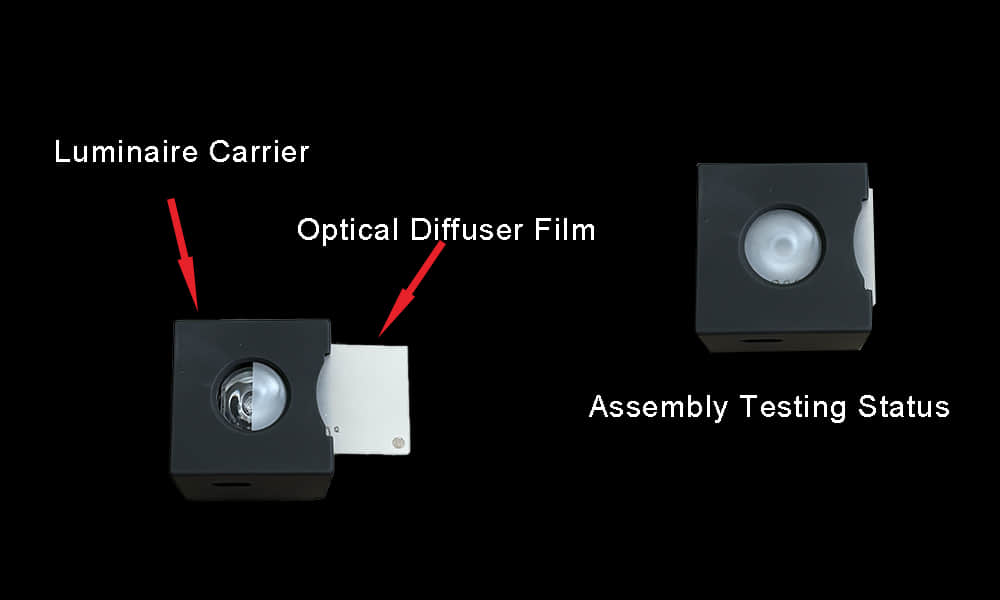

Crucial Installation: Orientation is Key

To extract maximum performance, proper installation is non-negotiable: The structured side (rough side) must face the Light Source (LED).

-

Correct Installation (Structure to LED): The micro-structures engage light rays immediately as they exit the primary optic, effectively shaping the beam.

-

Incorrect Installation (Smooth to LED): Increases internal reflection errors, leading to reduced beam size and lower optical efficiency.

3. Key Applications: Solving Real-World Problems

The true value of Micro-Structure Diffusion Film is revealed in solving specific optical challenges.

A. Small Indoor Fixtures: The "Clean Beam" Upgrade

In high-end retail lighting, beam edge quality is critical. A common issue with COB downlights is the "Secondary Halo" outside the main beam angle.

The Film Solution:

Placing our 0.175mm Thin Diffusion Film at the light exit surface:

-

Halo Elimination: Catches and redirects stray photons.

-

Visual Comfort: Transforms a "Hard Cutoff" into a "Soft Cutoff", significantly lowering UGR (Unified Glare Rating).

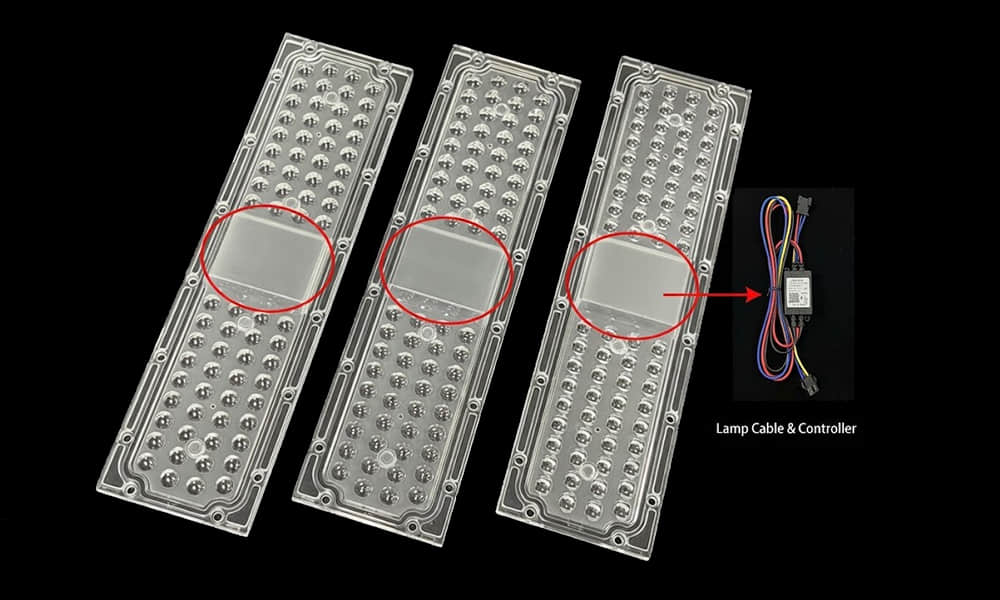

B. Linear Lighting: Inventory & Field Flexibility

Structure & Installation:

A "Slot-in" design in the aluminum profile allows films to be slid in during assembly or retrofitted on-site, offering unparalleled flexibility.

C. The Perfect Wall Wash

Wall washing is a major challenge in architectural lighting. Standard lenses create a hot spot and leave a Dark Zone at the top, with light decaying towards the bottom.

The Solution:

Using a High-Power Narrow Beam Spot (4°) with our Asymmetric Shaping Film.

-

Beam Stretching: Transforms a 4° spot into a 4° × 60° Oval.

-

Top-Edge Fill: Diffusive properties kick light upwards, eliminating the Dark Zone.

-

Throw Capability: The narrow base lens maintains high intensity to reach the top of facades.

The result is a Full-Coverage Wash that looks painted on.

D. Installation Guide: Ensuring Structural Success

The film must be held flat.

-

For Outdoor (IP65/IP66): Mechanically clamp between the Primary Lens Holder and Glass Cover. Use a seating rib to prevent sliding.

-

For Indoor Downlights: Use a dedicated Press Ring. Sequence: Lens → Film (structured side down!) → Press Ring.

-

Warning: Maintain a 2-3mm distance from the LED chip to prevent thermal deformation.

Thermal Considerations: For high-power (100W+) "Power Beast" fixtures, we offer High-Tg (Glass-Transition) film variants upon request.

4. Manufacturing Capability & Partnership

Innovation must be deliverable at scale. Asahi Optics invests in infrastructure for massive industrial rollouts.

Large-Format Mold Capacity (1000 × 600mm)

We operate high-precision tooling for Large-Format Optical Sheets, unlike suppliers limited to small molds.

-

Seamless Integration: Produces single-piece sheets for long Linear Lighting runs, avoiding unsightly seams.

-

High Volume Consistency: Automated lines ensure uniform micro-structure density and identical optical performance across thousands of units.

-

Custom Cutting: We can also precision-cut films to match any single lens or custom design.

Let's Solve Your Lighting Challenge

Whether eliminating the yellow ring in a museum spotlight or achieving a perfect skyscraper wash, Asahi Optical Diffusion Film is your essential tool.

Ready to upgrade your fixture's performance?

Contact our engineering team. Share your target beam angle and application scenario. We will provide relevant samples and case studies to demonstrate how a simple layer of film can revolutionize your light quality.