In the mold manufacturing process, mold polishing is an extremely crucial step that directly affects the mold's performance and the final product quality. An unpolished or poorly polished mold may produce products with surface defects, dimensional deviations, and other issues, which seriously compromise the product's appearance and usability. This is particularly significant for manufacturers of precision components like LED lenses and optical lenses, where even minor mold imperfections can lead to irreversible performance flaws in the end products.

Therefore, gaining an in-depth understanding of the hand polishing process for molds is of great guiding significance for you to accurately select high-quality molds that meet your specific needs, especially when it comes to LED optical components and custom optical designs.

The Process Flow of Mold Polishing

The process flow of mold polishing typically involves multiple stages. The first stage is rough polishing, whose main purpose is to remove obvious defects, roughness, and oxide layers from the mold surface caused by previous processing (such as precision milling, EDM, grinding, etc.), and initially smooth the mold surface. This step often uses a rotating surface polisher with a speed of 35,000 - 40,000 r/min, followed by manual oilstone grinding. Strip oilstones are used with kerosene as a lubricant or coolant, usually in the order from 150# to 1000#.

Next is semi-finish polishing. At this stage, sandpaper and kerosene are mainly used to further improve the smoothness of the mold surface. Sandpaper grits are used in the order of 400#, 600#, 800#, 1000#, 1200#, and 1500#. However, it should be noted that 1500# sandpaper is only suitable for hardened mold steel (above 52HRC); using it on pre-hardened steel may cause surface damage and affect the polishing effect— a key consideration for lens mold manufacturers aiming for precision.

Finally, there is finish polishing. Finish polishing mainly uses diamond paste. If a polishing cloth wheel is mixed with diamond powder or paste for grinding, the common grinding order is 9μm (1800#), 6μm (3000#), and 3μm (8000#) to remove the hair-like grinding marks left by the previous sandpaper. Then, a felt pad and diamond paste are used for more precise polishing, in the order of 1μm (14000#), 1/2μm (60000#), and 1/4μm (100000#). This level of precision is essential for manufacturing molds used in LED optical lenses, where surface smoothness directly impacts light transmission efficiency.

Hand Polishing: The Unique Charm of a Traditional Craft

(I) Definition and Process Analysis

Hand polishing is a process that relies on manual operation, using specific tools and abrasive materials to perform fine grinding and polishing on the surface of an object. It is a traditional craft that requires rich experience and exquisite skills, and plays an irreplaceable role in mold manufacturing, especially in the production of optical lens molds and LED optics molds.

Hand polishing uses a variety of tools. Common ones include sandpaper; according to different grits (such as 400#, 600#, 800#, etc.), the particle size varies, which can meet the needs of different stages from rough polishing to finish polishing. Oilstones are also important tools; strip oilstones, when used with lubricants such as kerosene during polishing, can effectively remove tool marks and EDM marks on the mold surface. Polishing paste is used in the final finish polishing stage, which can significantly improve the gloss of the mold surface. In addition, tools such as bamboo chips and polishing wheels are also used for auxiliary polishing, especially when dealing with complex curved surfaces of custom optical lenses.

The specific operation steps of hand polishing are relatively complex. The first is the rough polishing stage, where sandpaper or oilstones with coarser grits are used to remove obvious defects, roughness, and oxide layers on the mold surface caused by previous processing, and initially smooth the mold surface. Then comes the semi-finish polishing stage; sandpaper with gradually increasing grits (i.e., gradually finer particles) is selected to further refine the texture of the mold surface and reduce surface roughness. Finally, the finish polishing stage uses polishing paste combined with wool balls or polishing wheels for fine grinding, so that the mold surface achieves an extremely high smoothness and presents a mirror-like effect. Throughout the process, operators need to rely on experience and feel to accurately control the strength, angle, and speed to ensure the uniformity and stability of the polishing effect— a critical factor for lens optical design realization.

(II) Comparison with Mechanical Polishing

Hand polishing and mechanical polishing each have their own advantages and disadvantages, and play different roles in different scenarios. For led optics manufacturers, choosing the right polishing method is crucial to ensuring product quality.

In terms of precision, hand polishing has obvious advantages when dealing with complex curved surfaces, fine textures, and local finishing of molds with extremely high precision requirements. Skilled craftsmen can flexibly adjust the polishing strength and angle based on rich experience and sensitive touch, achieving high precision that is difficult for mechanical polishing to reach. For example, in the polishing of some precision optical molds, hand polishing can accurately handle tiny defects and complex shapes on the mold surface, ensuring the imaging quality of optical components. Although mechanical polishing performs well in overall flatness and consistency, it is often difficult to achieve the precision of hand polishing for some complex structures and detailed parts due to the limitations of equipment and procedures— a gap that is particularly noticeable in LED lens mold manufacturing.

In terms of flexibility, hand polishing is highly flexible. Craftsmen can change the polishing method and tools at any time according to the actual situation of the mold surface to adapt to various irregular shapes and special requirements. Whether it is deep grooves, special-shaped structures, or narrow spaces, hand polishing can easily handle them. In contrast, mechanical polishing usually requires programming and debugging according to the shape and size of the mold. For molds with large shape changes or temporary modifications, the adjustment process is cumbersome and the flexibility is poor— a disadvantage that can be costly for custom lens production where designs often vary.

Cost is also an important consideration. Hand polishing mainly relies on manual operation, so the labor cost is relatively high, and the efficiency is low. The cost will increase significantly during mass production. However, for small-batch and high-precision mold processing, the total cost of hand polishing may be lower because there is no need to invest a lot of equipment costs. Mechanical polishing equipment is expensive, requiring a lot of capital investment in the early stage for equipment purchase, installation and commissioning, and later maintenance. However, during mass production, the unit cost will decrease with the increase in output due to high efficiency— a factor that lens design manufacturers need to weigh based on production scale.

To sum up, hand polishing excels in precision and flexibility, making it suitable for mold processing with complex structures, high precision requirements, and small batches; mechanical polishing, on the other hand, has more advantages in efficiency and consistency in mass production, and is suitable for mold manufacturing with regular shapes and large-scale production. In the actual mold manufacturing process, hand polishing and mechanical polishing are often combined according to specific needs to give full play to the strengths of both and achieve the best polishing effect and economic benefits. This combination is widely adopted in the production of LED optical lenses and custom optics.

Why Hand Polishing Is Indispensable

(I) Enhancing Surface Quality

For injection molds, surface quality is a crucial factor. The micro-state of the mold surface will be directly replicated on the injection-molded product, so a mold with poor surface quality will inevitably produce products with various defects. This is especially true for LED lenses, where surface smoothness directly affects light transmittance and propagation control.

Hand polishing can effectively eliminate micro-defects on the mold surface. During the previous processing of the mold, whether it is cutting, EDM, or grinding, tiny tool marks, pinholes, air holes, and other defects will be left on the mold surface. If these micro-defects are not removed, during the injection molding process, when the plastic melt fills the mold cavity, corresponding flaws will be formed on the product surface, such as scratches, pitting, unevenness, etc., which seriously affect the product's appearance quality and performance. For example, when producing precision electronic part housings, even extremely small surface defects may cause the housing surface to be uneven, affecting the product's appearance and assembly accuracy. For optical lenses, such defects can lead to light scattering and reduced optical performance.

Hand polishing is irreplaceable in achieving a high-gloss surface. Some high-end injection-molded products, such as optical lenses, high-end electronic product housings, and automotive lighting components, have extremely high requirements for surface gloss, often requiring a mirror-like effect. Relying on craftsmen's exquisite skills and delicate operations, hand polishing can make the mold surface achieve extremely high smoothness, meeting the production needs of these high-end products. Taking optical lens molds as an example, the surface gloss directly affects the imaging quality of the lens. Only through hand polishing can the roughness of the mold surface be reduced to a minimum, ensuring that the lens can image clearly and reducing imaging errors caused by light scattering and refraction— a key requirement for LED optics design.

(II) Ensuring Dimensional Accuracy

The importance of dimensional accuracy for injection-molded products is self-evident. Accurate dimensions are the key to ensuring that the product can be used normally and assembled smoothly with other components. For example, in automobile manufacturing, injection-molded parts need to fit closely with other mechanical components; if there is a dimensional deviation, it may lead to a decline in the overall performance of the car, or even safety hazards. In electronic products, dimensional accuracy deviations may affect product assembly and the layout of internal circuits, resulting in the product being unable to work normally. For custom LED lenses, precise dimensions are essential to meet specific lighting application requirements.

When dealing with complex shapes and fine structures, hand polishing has unique advantages in ensuring the dimensional accuracy of the mold. For molds with complex curved surfaces, tiny holes, narrow grooves, and other structures, mechanical polishing is difficult to accurately control the polishing position and degree due to tool limitations, which may easily cause excessive local dimension wear or insufficient polishing. Skilled hand polishers, relying on rich experience and sensitive touch, can accurately judge the polishing degree of each part of the mold surface, avoiding dimensional deviations caused by over-polishing. When polishing molds with fine patterns or designs, hand polishing can carefully handle every detail, ensuring the integrity and clarity of the patterns and designs while ensuring the overall dimensional accuracy of the mold— a critical aspect for lens optical design implementation.

(III) Extending Mold Service Life

During use, molds will be subject to various factors that cause wear and corrosion, thereby shortening their service life. Wear is mainly caused by the friction between the plastic melt and the mold surface during injection molding, and the mechanical friction between various components when the mold is opened and closed. Corrosion may be caused by chemical reactions between additives in plastic raw materials, release agents, and other chemical substances and the mold surface. For example, when injecting plastic containing corrosive additives (such as certain flame retardants), the mold surface is easily subject to chemical corrosion, resulting in rough surfaces and pitting, which in turn affects product quality and mold life. This is a key concern for lens mold manufacturers looking to optimize production costs.

Hand polishing plays an important role in removing stress concentration points and preventing crack propagation. During the manufacturing and use of molds, stress concentration will occur inside, and these stress concentration points are likely to cause cracks and their propagation, eventually leading to mold damage. Through fine grinding and polishing, hand polishing can make the stress distribution on the mold surface more uniform, eliminate potential stress concentration points, and thereby reduce the risk of cracks. In addition, for molds that have already developed tiny cracks, hand polishing can properly treat the cracks, slow down the propagation speed of the cracks, and extend the service life of the mold— a benefit that directly impacts the production efficiency of LED optics manufacturers.

Hand polishing is also highly effective in enhancing the corrosion resistance of molds. The mold surface after hand polishing is denser and smoother, reducing the contact area and reaction sites between chemical substances and the mold surface. This makes chemical corrosion more difficult, thereby improving the corrosion resistance of the mold. For example, when injecting plastic containing acidic additives, the polished mold surface can better resist the erosion of acidic substances, reduce corrosion damage on the mold surface, and extend the service life of the mold. This is particularly important for LED optics molds that may come into contact with various plastic materials during production.

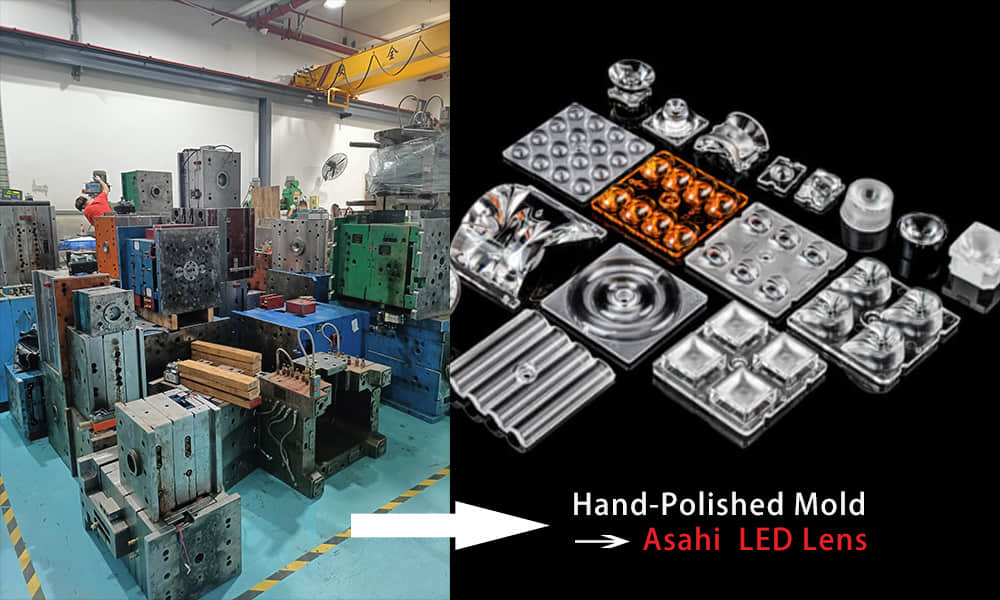

Asahi Optics: An Outstanding Practitioner of Hand Polishing

As a Chinese manufacturer specializing in LED lenses with years of experience in the industry, Asahi Optics (also referred to as Asahi) exports its products to many countries in Europe and South America. In the manufacturing process of injection molds, Asahi Optics attaches great importance to the hand polishing process, recognizing it as a cornerstone of product quality.

The company has extensive experience in mold development and lens production. Since its establishment, it has been committed to providing high-quality LED lens products to global customers. We deeply understand that the quality of injection molds directly affects the performance of LED lenses, and hand polishing plays a key role in this process. As a professional optics manufacturer and lens design manufacturer, we integrate hand polishing excellence into every production link.

At Asahi Optics, every operator involved in mold hand polishing has more than 10 years of rich experience. Relying on their exquisite skills and dedication to details, they ensure that every mold meets the highest polishing standards. Whether it is a mold with a complex curved surface or a small mold with extremely high precision requirements, our craftsmen can use skilled hand polishing techniques to achieve the ultimate surface quality. This commitment to precision makes us a trusted partner for custom optics and custom optical lens requirements.

In the production of LED lenses at Asahi Optics, every link from the initial mold design to the final product formation is strictly controlled for quality. Our molds not only excel in surface quality but also surpass peers in dimensional accuracy and durability. This enables our LED lenses to have excellent light propagation capabilities and controllability, widely used in indoor lighting, outdoor lighting, sports lighting, large-area lighting, automotive lighting, medical lighting, industrial applications, and other fields. Our best-selling product, the outdoor street lamp lens, is a testament to the quality achieved through rigorous hand polishing and precise mold manufacturing.

If you are interested in our products, welcome to visit the official website of Asahi Optics: https://www.asahi-optics.com/ to learn more about our company and products. You can also access our customization page https://www.asahi-optics.com/led-optical-design/ to obtain professional custom design services. We will tailor the most suitable LED lens solution for you based on your specific needs, whether you require customize LED lens or customize optics.

Hand Polishing: The Finishing Touch for Injection Molds

As an indispensable part of injection mold manufacturing, hand polishing plays a key role in improving mold surface quality, ensuring dimensional accuracy, and extending mold service life with its unique advantages. It is not only an inheritance of traditional crafts but also an important guarantee for the pursuit of high-quality and high-precision products in modern manufacturing. For led optics manufacturers and lens mold manufacturers, mastering and applying hand polishing technology is a core competitiveness.

With the continuous development of the manufacturing industry, the requirements for injection molds are getting higher and higher, and the hand polishing process is also constantly innovating and progressing. In the future, hand polishing will be combined with advanced technologies and equipment to further improve polishing efficiency and quality, continuing to contribute to the development of high-precision manufacturing fields such as LED optics and optical lens production.