Have you ever walked down a street at night and noticed how some lights create a smooth, carpet-like illumination, while others leave dangerous dark spots or blinding "zebra stripes" on the road?

The difference often isn't the brightness of the bulb—it's the optical anatomy of the fixture.

While many city planners and contractors rush to upgrade from legacy High-Pressure Sodium (HPS) to LED to save energy, they often overlook the most critical component that controls where that energy actually goes: The Optical Lens.

In this comprehensive engineering guide, we dissect the anatomy of a high-performance modern street light. We will explore the critical synergy between LED chips, thermal structures, and precision optics, and help you understand why choosing the right lens manufacturer is just as important as choosing the right LED.

A Quick History: The Evolution of Street Optics

To understand why modern lenses are necessary, we must look at where we came from.

-

The Era of Glass & Reflectors (1900s - 2000s): Traditional street lights (HPS or Metal Halide) relied on a simple principle: a bright bulb in the center and an aluminum reflector behind it. The front cover was usually tempered glass. The Problem: This method was incredibly inefficient. Nearly 30% of the light was trapped inside the fixture or "spilled" into the night sky, creating light pollution and wasting electricity.

-

The Early LED Era (2010s): When LEDs first appeared, manufacturers simply placed LED chips behind a flat sheet of plastic. While energy-efficient, the light was harsh, glaring, and uncomfortable for drivers.

-

The Age of Precision Optics (Today): Today, we utilize Integrated Optical Engines. We no longer rely on reflection; we use Refraction and TIR (Total Internal Reflection). Each individual LED chip has its own dedicated lens, calculated to micro-millimeter precision to direct light exactly where it is needed—on the road, not in the driver's eyes.

LED Chips

The Raw Power Engine

At the heart of the system is the LED package. Unlike the fragile filaments of the past, modern street lights utilize robust Surface Mount Diodes (SMD).

-

3030 & 5050 Packages: These are the industry standards. They are small, efficient, and generate less heat than older technologies.

-

The Lambertian Challenge: A raw LED chip emits light in a wide 120° cone (known as a Lambertian distribution). If you simply place this over a road, you get a bright "hot spot" directly under the pole and total darkness between poles.

This is why a powerful engine needs a skilled driver. In lighting, that driver is the Optical Lens.

Optical Lenses

Sculpting Light with Asahi Optics

This is where Asahi Optics transforms raw light into a functional tool. As optical designers and mold manufacturers, we don't just "cover" the LED; we manipulate photons using TIR (Total Internal Reflection) technology.

In modern roadway lighting, "one size fits all" does not exist. Different road classes require different optical "anatomies":

1. The "Cutoff" Master for Urban Roads (50x50mm Array)

In residential areas or city centers, the biggest enemy is "Light Pollution." You need light on the road, not in people's bedroom windows or the night sky.

For these scenarios, we engineer lenses with a strict Cutoff Line.

-

The Solution: 2X4 Arrays 5050LED T2 Excellent Cutoff Street Light Lens

-

The Engineering: This 50x50mm module fits standard Zhaga footprints but features a specialized surface curvature that creates a Type II-Medium (T2M) distribution with a sharp cutoff.

-

The Effect: It maximizes longitudinal uniformity (lighting up the road ahead) while strictly limiting backlight, ensuring compliance with "Dark Sky" regulations.

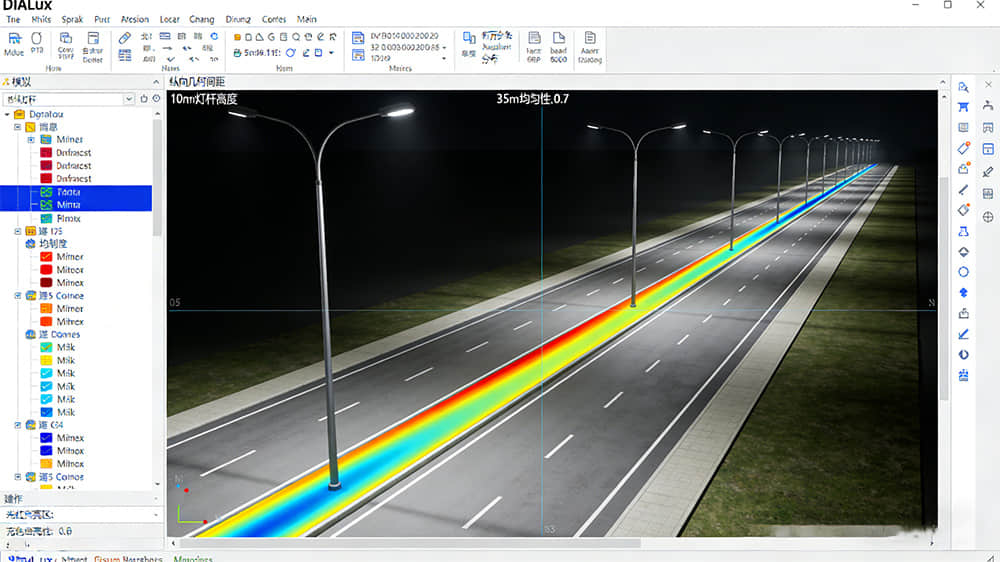

2. The "Distance Runner" for Highways (Long Pole Lens)

On highways or bridges, poles are often spaced far apart to save infrastructure costs. A standard lens would leave dangerous dark patches between poles. You need a lens that can "throw" light further.

-

The Solution: High Quality PC Lens 5050LED T2M For Long Pole Distance

-

The Engineering: This 173x71.4mm lens utilizes a larger optical surface area to collimate light from high-power 5050 LEDs.

-

The Effect: It stretches the beam pattern, allowing for wider pole spacing (up to 4-5 times the mounting height) while maintaining high luminance uniformity. This directly reduces the number of poles needed for a project.

3. The "All-Weather Shield" (IP66 Waterproof Module)

Traditional street lights require a separate glass cover for protection, which reduces light transmission (approx. 10% loss). Modern engineering combines the lens and the cover into one.

-

The Solution: IP66 Street Lighting 3x8 Lens 5050LED T2M-Cutoff

-

The Engineering: We integrated a silicone gasket channel directly into this 24-LED module. Made from high-grade UV-stabilized PC, it acts as both the optical controller and the protective shield.

-

The Effect: It achieves an IP66 rating without an extra glass cover, increasing overall System Efficacy (LPW) and simplifying the fixture assembly process for manufacturers.

Material Science (PMMA vs. PC)

Why Material Choice Matters

An often-overlooked part of the anatomy is the material of the lens itself. As a mold factory, we guide our clients to make the right choice based on the environment.

-

PMMA (Acrylic):

-

Pros: Extremely high light transmittance (93%) and excellent UV resistance. It will not yellow for 10+ years.

-

Best For: General street lighting and architectural projects where optical efficiency is priority #1.

-

-

PC (Polycarbonate):

-

Pros: Virtually unbreakable. High heat resistance (up to 120°C).

-

Best For: Harsh environments (like tunnels or factories) where high heat or physical impact (vandalism) is a risk. Our AF Series is available in high-grade PC for these tough applications.

-

The Thermal & Smart Backbone

The Future of Integrated Modules

Heat is the enemy of LEDs. High "Heat Flux Density" can cause lenses to warp and chips to fail. Therefore, the lens must be physically integrated with the thermal structure.

In our latest innovation, the 72-LEDs Multi-Module, we re-imagined this relationship to prepare for the Smart City era.

Instead of a solid block of plastic, we engineered a central groove (approx. 40x40mm) directly into the optical module.

-

Thermal Logic: This allows the lens to fit perfectly around the heat dissipation ribs of the fixture, maximizing airflow and cooling the LEDs more effectively.

-

Smart Logic: This groove acts as a "Smart Bay". It provides a dedicated, hidden space for intelligent controllers, IoT sensors (like Zigbee or LoRa), or messy cabling. It makes the street light not just a light, but a smart node.

5 Factors to Consider When Choosing Street Light Optics

If you are a lighting manufacturer or a project manager, how do you choose the right optical anatomy? Here is a checklist from our engineering team:

-

Beam Angle Matching: Do not just ask for "street light lenses." Ask for Type II (for long narrow roads) or Type III (for wider roads). Using the wrong angle (like a flood beam) will waste 50% of your light.

-

LED Compatibility: Ensure the lens is optimized for your specific chip size (3030 vs 5050). Putting a small 3030 chip in a lens designed for a 5050 can result in poor beam control.

-

Lens Material: If your project is in a high-UV area (like South America or Australia), insist on UV-stabilized PMMA or PC to prevent yellowing.

-

Integration Level: Are you buying single lenses (like AN/AF Series) for a custom design, or do you need a pre-made module (like our 72-LEDs module) for quick assembly?

-

Manufacturer Capability: Does your supplier have in-house mold making? This is crucial if you ever need to tweak the beam angle slightly for a specific government tender.

Conclusion

Modern street lighting is no longer just about putting a bulb on a pole. It is a complex science of anatomy, involving the seamless integration of SMD chips, thermal management, and precision optical lenses.

-

Does your fixture utilize TIR optics to prevent light pollution?

-

Does it employ specific beam angles (like the AN/AF Series) for architectural details?

-

Is the thermal design intelligent enough to house future smart controls?

At Asahi Optics, we bridge the gap between mold engineering and optical design. We provide the essential organs—from individual lenses to fully integrated modules—that make modern street lights efficient, beautiful, and smart.

Ready to upgrade your fixture's performance? [Contact our engineering team today] to request IES files, material datasheets, and design support for your next project.