1. Why LED Lens Maintenance Matters

LED lenses play several core roles in every lighting system, namely shaping and controlling light distribution, as well as protecting the LED light source and ensuring stable optical efficiency.

However, over time, even the best lenses can experience yellowing, surface damage, or reduced transmittance if not maintained properly.

Proper maintenance extends the life of the LED luminaire, maintains optical clarity, and prevents unwanted light diffusion or color shift. For commercial, architectural, or industrial lighting applications, following a structured maintenance procedure ensures that every luminaire continues to perform as designed.

2. Common Causes of Lens Aging and Damage

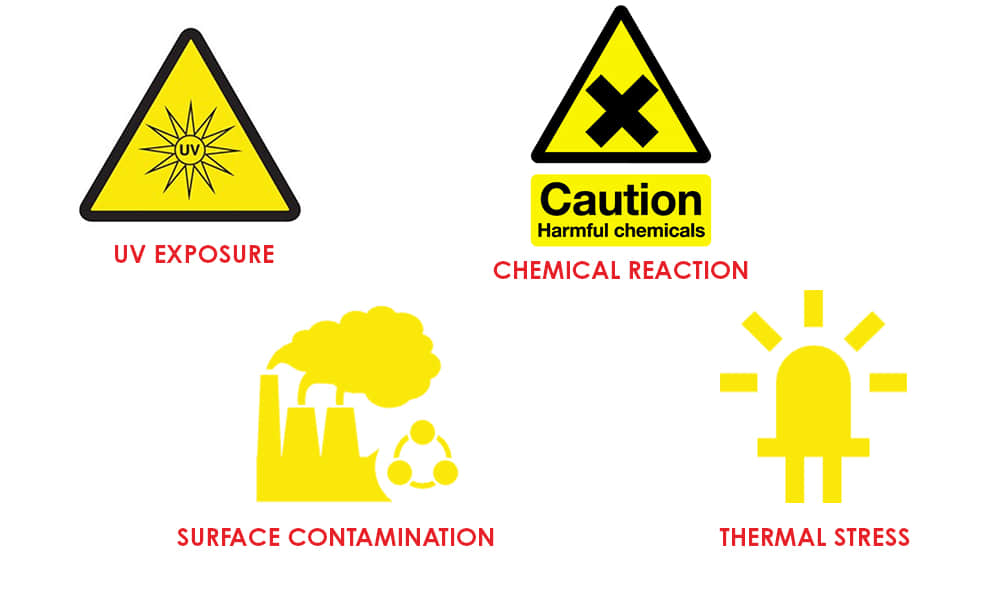

Despite using durable materials like PC or PMMA, LED lenses can still degrade under certain conditions. Understanding these factors helps users implement effective maintenance strategies.

- UV Exposure: Prolonged ultraviolet radiation causes material degradation and yellowing.

- Surface Contamination: Dust, oils, or airborne particles can adhere to the lens and scatter light.

- Chemical Reaction: Contact with solvents, ammonia, or alcohol-based cleaners can alter the molecular structure of the optical material.

- Thermal Stress: Poor heat dissipation in the luminaire accelerates aging and micro-cracking. Suitable ambient temperature for materials: PMMA (-40°C to +80°C) / PC (-40°C to +120°C).

- Mechanical Scratches: Improper handling or cleaning with rough materials can damage the optical surface.

These issues not only reduce transmittance but also distort the light beam, compromising overall lighting quality.

3. Proper Cleaning and Maintenance Steps

A consistent maintenance routine keeps lenses performing like new. Here’s how to safely clean and handle your LED lenses:

3.1 Cleaning Frequency

Adjust based on the environment. Indoor office lighting may require semi-annual cleaning, while outdoor or industrial fixtures might need quarterly attention.

3.2 Safe Cleaning Process

- Use mild soap and warm water with a soft, lint-free cloth.

- Avoid harsh industrial solvents (alcohol, ammonia, sulfuric acid, mineral oils, or petrol).

- Rinse gently and dry with a microfiber cloth to prevent streaks or watermarks.

3.3 Handling & Installation Precautions

- Always wear gloves when handling optical components to prevent fingerprints or skin oil contamination.

- Avoid applying excessive pressure during installation to prevent stress cracks.

3.4 Storage Recommendations

- Store in a cool, dry, and dust-free environment (recommended: -40°C to +70°C, humidity 30–95%).

- Keep lenses sealed until use to prevent airborne contamination.

For detailed cleaning examples, refer to our related article: The Link Between LED Lighting Quality and Lens Yellowing,Why Lenses Turn Yellow and How to Improve or Slow Down Yellowing Process

4. Best Practices to Extend LED Lens Lifespan

To maximize the service life of your optical components, consider the following best practices:

- Maintain a well-designed thermal management system in your luminaires.

- Avoid exposure to chemical environments such as oil fumes, acid vapors, or coastal salt mist.

- Regularly inspect lumen output and beam uniformity to detect early signs of lens aging.

- Use manufacturer-recommended housings and mounting systems to ensure structural compatibility.

- Consistent care not only preserves lens clarity but also maintains light efficiency and energy savings across the entire system.

Conclusion

In LED lighting, maintaining optical integrity is as important as designing for performance. Regular care and proper material selection work hand in hand to ensure the longevity and precision of every lighting project.

At Asahi Optics, our lenses are designed not only for superior light control but also for long-term stability under real-world conditions.