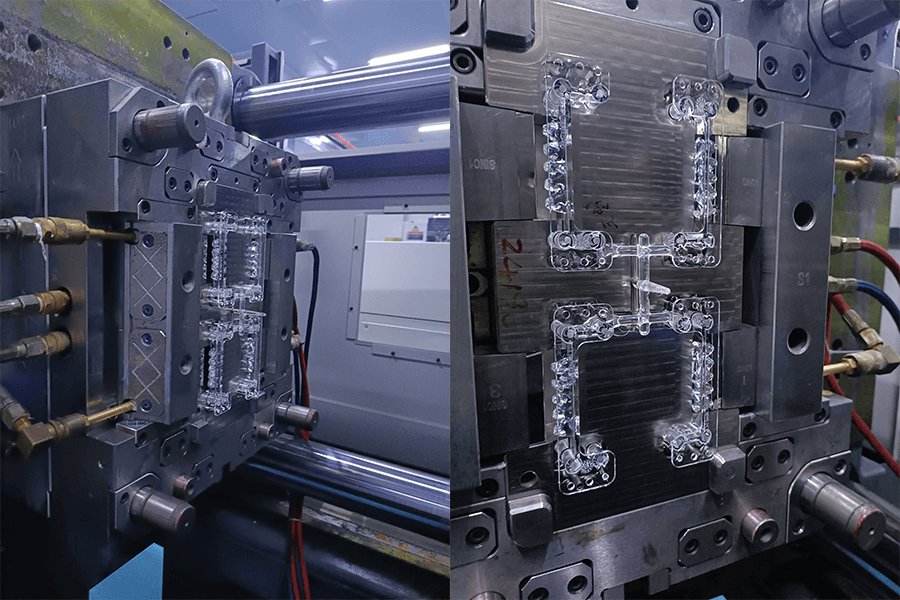

Asahi is one of the well-known precision plastic and optical mold manufacturers in China.Our mechanical engineers have 8-15 years of mechanical tooling design experience. They are skilled in simple and complex tooling designs. Let's talk about what factors will affect the injection mold in the production of optical lenses.

Select Different LED Lens Injection Material

Optical lenses are components of optical products. The mainstream materials on the market are PMMA and PC, with other less popular materials available to choose from based on your needs.

PMMA: It has higher light transmittance (over 93%), good injection molding fluidity, and easy molding.

PC: While its light transmittance is slightly lower (>88%), it offers strong impact resistance, drop resistance, and high-temperature resistance (long-term operating temperature approximately 120°C), making it suitable for high-temperature environments.

The specific material selection should be based on the lighting application and a comprehensive consideration of various factors.

Finished optical lenses are contaminated: yellowing and black spots

In 2023, a batch of 30,000 lenses was scrapped. The reason was that our project engineers discovered tiny black spots on some lenses during product inspection. To ensure product quality, this was an absolute no-no, so we scrapped the batch and started production.

The black spots were caused by the 0.8% moisture in the resin pellets and carbides in the nozzle tips. During each production run, we now check to see if the material temperature is too high, causing carbonization in the barrel, and if there is any carbonized material buildup inside the barrel. This helps prevent defects like yellowing and black spots on the lenses.

Dimensional variations between injection molded lenses

Product design requires fixed dimensions from the outset. While small precision errors are inevitable, thorough preparation can minimize these errors!

The main factors affecting the dimensions of injection molded products are the mold dimensions and the injection molding process parameters. This requires engineers with extensive project experience to successfully complete injection molding. This is why I mentioned earlier that Asahi has several experienced engineers.

LED lens product processing environment

There is another point that cannot be ignored in the production conditions of injection molding, that is the production environment.

Lens products require a very clean and dust-free environment. Whether it is the application of robots, laser cutting machines or manual packaging to improve production efficiency, every link needs to be kept clean and dust-free. Manual links need to wear gloves and other measures.

In our more than ten years of experience in injection molding, we've certainly encountered more than just these four problems, but I believe these are undoubtedly the most common. If you have a lighting project you are considering that requires optical lenses, Asahi is willing to help you.