In the evolving landscape of industrial lighting, the demand for highly efficient and precise optical solutions has led to continuous innovation in UFO high bay lens design. These lenses are not just protective covers for LEDs; they play a critical role in shaping light output, improving energy efficiency, and meeting diverse application requirements in industrial environments.

Importance of Optical Design in Industrial Lighting

The performance of industrial lighting systems depends heavily on accurate light distribution. The UFO high bay lens serves as the interface between LED sources and illuminated spaces, directly influencing beam control, uniformity, and glare management. A well-engineered lens design can optimize:

-

Illuminance levels to meet specific industrial standards

-

Energy consumption by reducing unnecessary light spill

-

Visual comfort through effective glare reduction

-

Safety and productivity in environments requiring consistent visibility

Key Design Parameters of UFO High Bay Lenses

Designing an efficient UFO high bay lens involves a balance of optical precision, material selection, and thermal considerations. The main factors include:

1. Beam Angle Control

The lens defines the beam angle, which determines how light is distributed in the environment. Common configurations include:

-

Narrow beams (40°–60°) for high-rack storage areas

-

Medium beams (90°) for balanced coverage

-

Wide beams (120°) for open factory floors

The selection depends on the ceiling height, task requirements, and desired lighting uniformity.

2. Optical Efficiency

High optical transmittance is essential for reducing energy loss. Advanced lens materials and surface treatments minimize absorption and scattering, allowing more light to reach the target area without increasing power consumption.

3. Thermal and Mechanical Performance

In industrial settings, UFO high bay lenses must withstand elevated temperatures, UV exposure, and mechanical stress. The integration of high-quality polycarbonate or PMMA materials ensures durability while maintaining optical performance over time.

4. Glare Management

Glare can reduce visual comfort and lead to eye strain. Innovative lens geometries, micro-structured surfaces, and diffuser integration are commonly used to balance high lumen output with reduced glare.

Emerging Trends in UFO High Bay Lens Design

The rapid evolution of industrial lighting technologies has introduced new trends in UFO high bay lens design:

-

High-efficacy optics: Achieving higher lumen-per-watt performance by minimizing optical loss.

-

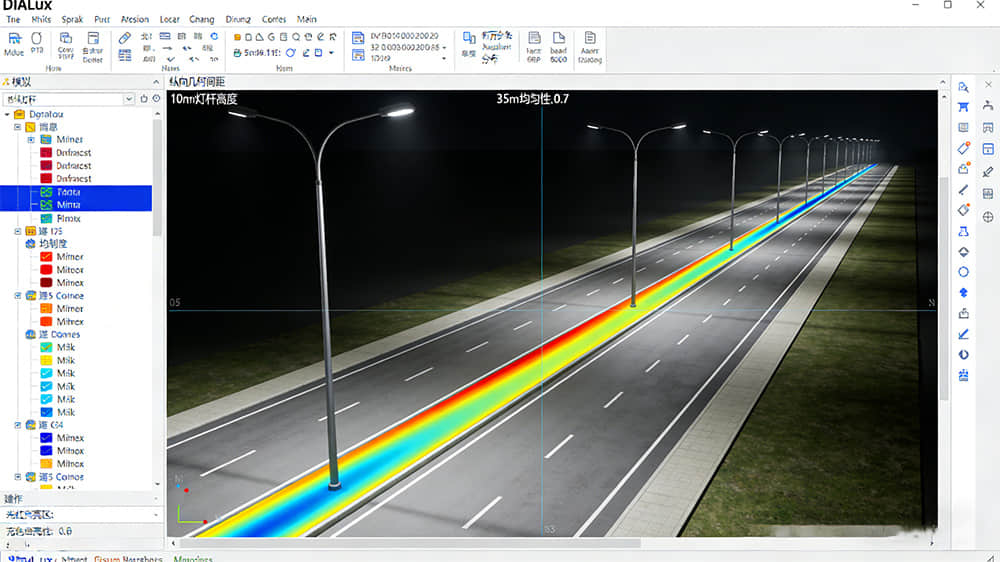

Precision-engineered beam shaping: Using freeform optics and advanced simulation software to customize light distribution.

-

Integration with smart lighting systems: Lenses designed for sensors and adaptive controls to optimize energy usage.

-

Sustainability focus: Employing recyclable materials and energy-saving optical architectures to align with environmental goals.

The UFO high bay lens is at the heart of efficient industrial lighting solutions, influencing beam distribution, energy efficiency, and visual comfort. As the industry moves toward higher performance standards and smarter systems, advances in lens design will continue to shape the future of industrial illumination.