First we need to know why choosing an LED lens manufacturer is so important

Poor quality LED lens manufacturers will waste your time, money and product quality. Some hidden costs, such as inconsistent optical performance or substandard quality control, I have seen some companies waste more than 6 months to fix lens defects simply because they chose suppliers based on price.

Knowing how important it is to choose an LED lens manufacturer, we can think that choosing the right LED lens manufacturer should include the following points:

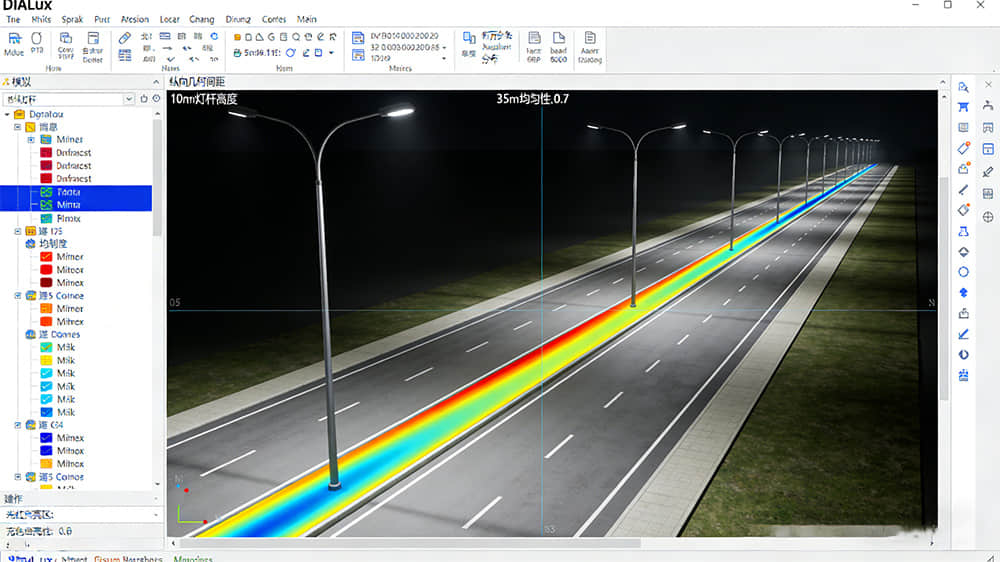

Optical design capabilities

The manufacturer should help optimize your design, such as the ability to customize beam angles and the ability to quickly make prototypes. For example, Asahi's Optical Design and Simulation (3-10days), Prototype Make and Sample Test (5-15days).

The specific process can be moved to the LED OPTICAL DESIGN page to view

Production quality control

Project engineers follow up and check and test every step of mold and product production to ensure that the samples meet customer requirements before mass production is arranged.

For example, the light transmittance of our PMMA material is at least >93%, and the lens for outdoor use can provide anti-yellowing coating

Communication and price transparency

At Asahi, every salesperson knows that effective and fast communication is the fastest way to improve customer satisfaction, so we will reply to customers' emails within 24 hours, provide real-time production updates, and clearly explain the price details (no hidden fees).

Conclusion

From the above, we can see that choosing the right custom LED lens manufacturer, we believe that it includes these three points (optical design capabilities, production quality control, communication and price transparency).

Asahi has been in the LED lens industry for nearly 20 years and has been adhering to these principles to promote its products to the world. Looking forward to any cooperation with you