10-20years optical design experience, skilled in customized optical design solutions. We are skilled in custom designs for street lights, high bay lights, commercial lights, Reflector, police car lights, bicycle lights, flashlights, Etc.

20 years of mechanical tooling design, skilled in advanced and complex tooling design provide a one-step tooling design without tooling modification.

The main software used for the optical design: TracePro, LightTools, DiaLux, SolidWorks

TracePro

LightTools

DiaLux

SolidWorks

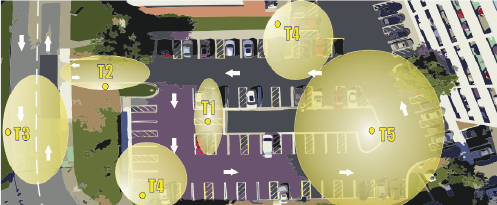

The North American Road Lighting Standards IES Classification—LED Lens series

TYPE II, TYPE III, TYPE IV, and TYPE V are widely used for street lighting and outdoor lighting requirements

The T2, T3, T4,T5 Optical light distribution designed by Asahi Optics has been optimized and combined with the road standards of European and American countries, which can achieve the height distance of the road with the height ratio of 6:1 and less backlight of the road, the UI>0.8, U0 index can reach the standard of ME3.

Flexible lens module size compatible with different LED sizes to meet the power requirements of different road lighting and area lighting.

Tips: LED lens plays a core role in LED lighting. The professional optical design provides the best light distribution solution for high-end lighting products. The quality of LED lens will directly affect the luminous light distribution, efficiency, lumen depreciation, and lifetime of luminaries.

Receive Customer's Design SPEC

Optical Design and Simulation

(3-10days)

Prototype Make and Sample Test

(5-15days)

Mass Production Mould Processing

(28-35days)

Production Trial and Sample Approval

(3-5days)

Customer Signs the sample for Mass Production

We provide complete solutions from optical design to mold manufacturing, ensuring precision and efficiency in every aspect

Optical Design serves as the foundational stage of the entire process, with the core objective of ensuring the lens meets predefined optical specifications while providing accurate references for subsequent mold design.

Upon receiving design requirements, the optical engineer's primary task is to verify the completeness of all relevant documents to ensure no design information is missing. The essential documents and their purposes are as follows:

Based on the 3D drawings of the optical lens, the mold engineer utilizes 3D design software such as Pro/E, UG, and SolidWorks to complete the comprehensive 3D structural design of the mold. The drawings must encompass all critical components including the cavity, core, runner system, gate, cooling channels, and ejection mechanism to ensure the mold structure meets injection molding requirements.

After the mold drawings are confirmed, the procurement process for core mold materials is initiated. To ensure the mold's wear resistance, polishing performance, and service life, the mold base, mold frame, and mold core of the lens mold are made of imported ASSAB S136 steel. This steel offers excellent corrosion resistance and mirror polishing potential, making it an ideal material for optical molds.

CNC Machining utilizes computer-programmed controls to direct precision cutting tools, executing the primary shaping of mold cavities and cores. Its accuracy fundamentally determines the dimensional precision of the mold base.

Wire EDM (Wire Electrical Discharge Machining) operates on the principle of electrical discharge erosion, making it particularly suitable for machining non-rotational asymmetric holes and sharp corner structures in molds. It can perform precision machining after quenching, effectively avoiding distortions caused by heat treatment.

EDM (Electrical Discharge Machining), while sharing the same electrical discharge erosion principle as Wire EDM, utilizes electrodes complementary to the cavity shape for three-dimensional copy milling. This process excels at handling deep cavities, narrow slots, and complex surfaces within molds, enabling the creation of geometries unachievable through traditional machining methods.

Manual Polishing remains an irreplaceable core process in current manufacturing technology, where the experience and judgment of skilled technicians directly determine the optical quality of the mold surface. Experienced technicians perform meticulous surface polishing to achieve a mirror finish that meets stringent optical product requirements.

Mold Trial serves the core objective of verifying mold performance and optimizing injection parameters, thereby establishing a reliable foundation for mass production. Mold engineers are responsible for assembling the molds and conducting trial runs, inspecting both mold functionality and product quality to ensure the mold can consistently produce qualified optical products.

Asahi Optics welcomes your questions, inquires and feedback. Please use the form below or contact us at any of the addresses below. Our sales team will get back to you shortly.