A precision mold design workflow from concept to finished product, ensuring the highest standards are met at every stage.

Upon receiving the 3D optical lens drawings, our mold engineers conduct a detailed requirements analysis to evaluate design feasibility, ensuring the mold structure meets all technical specifications for injection molding.

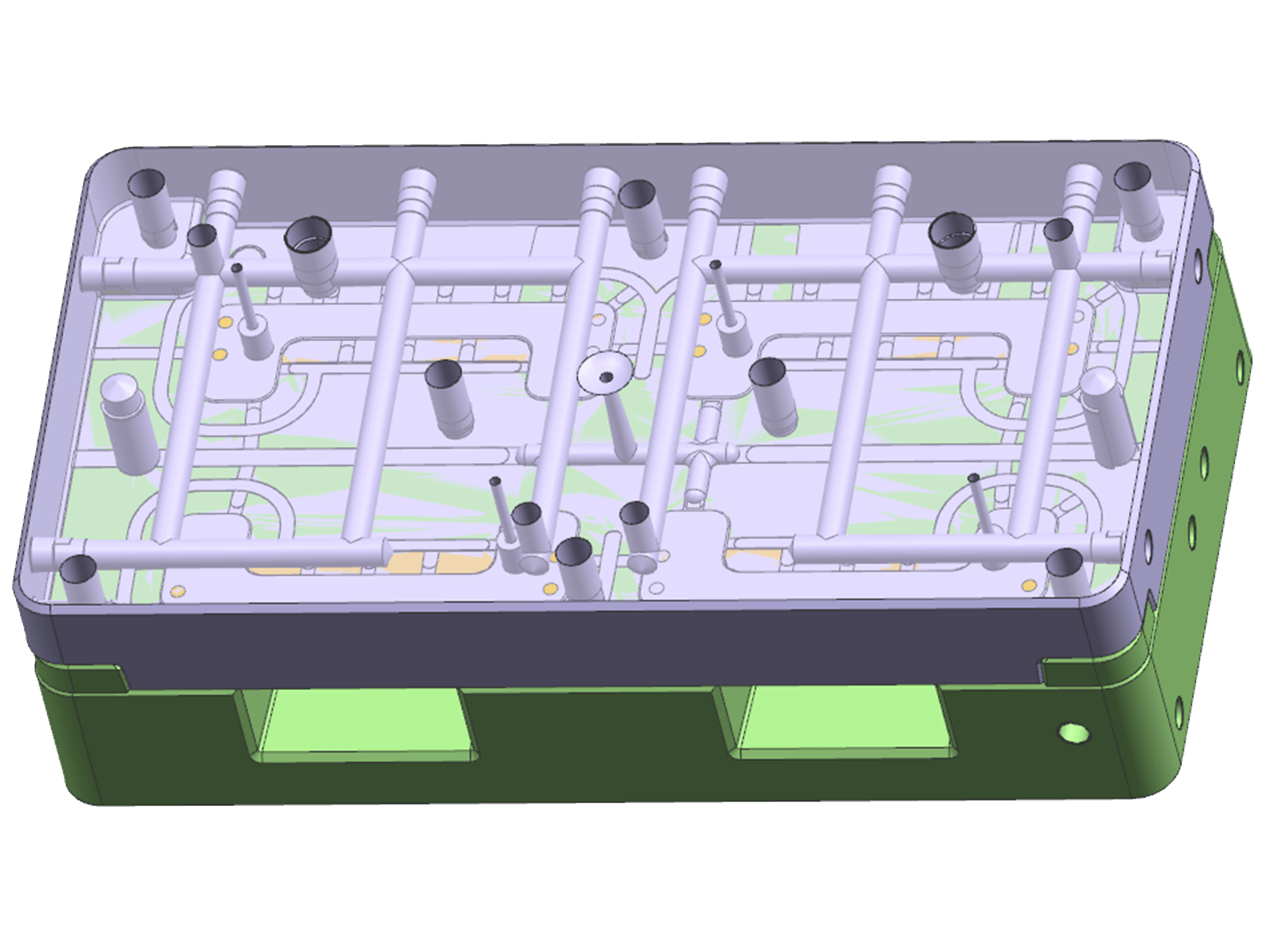

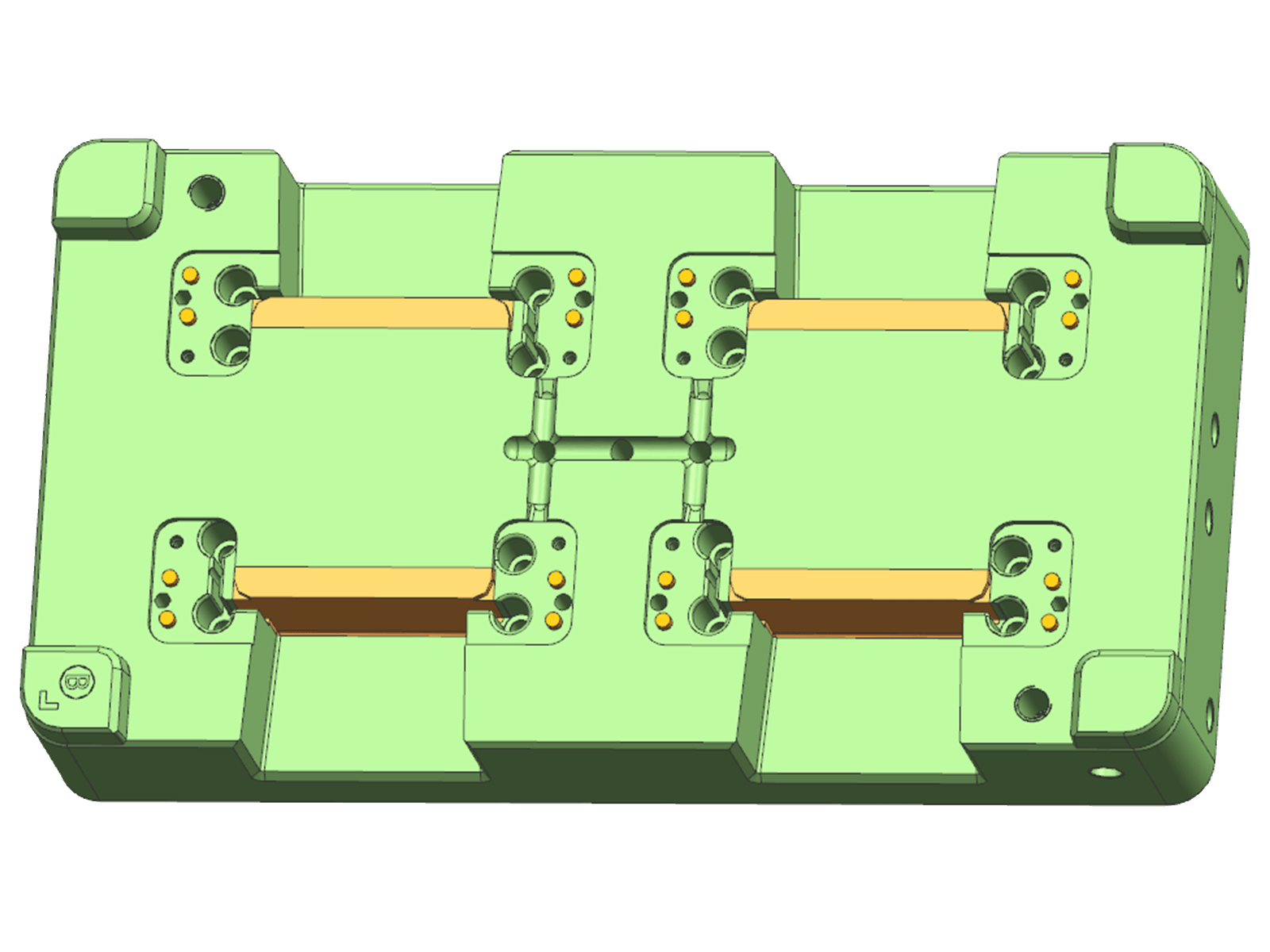

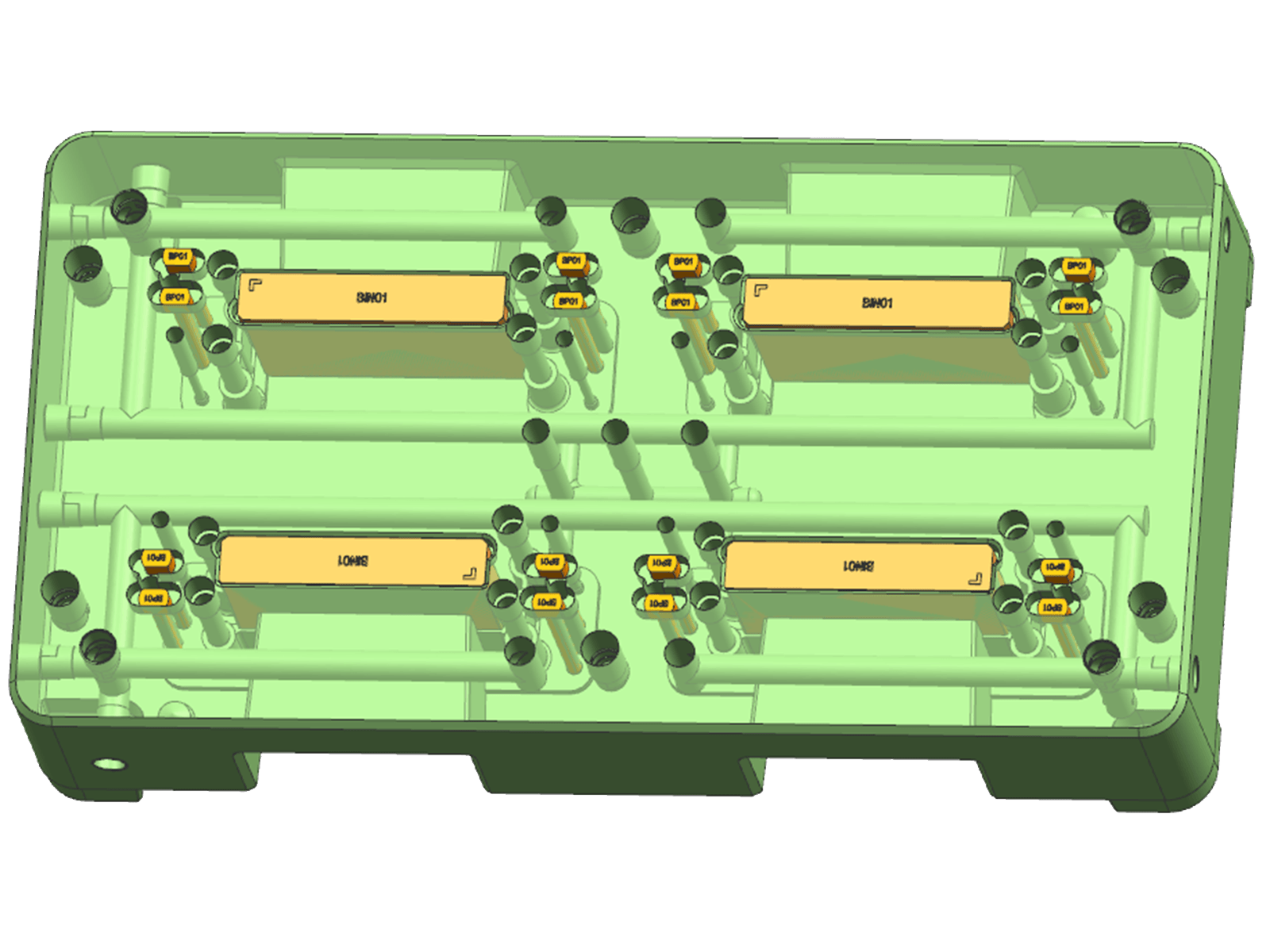

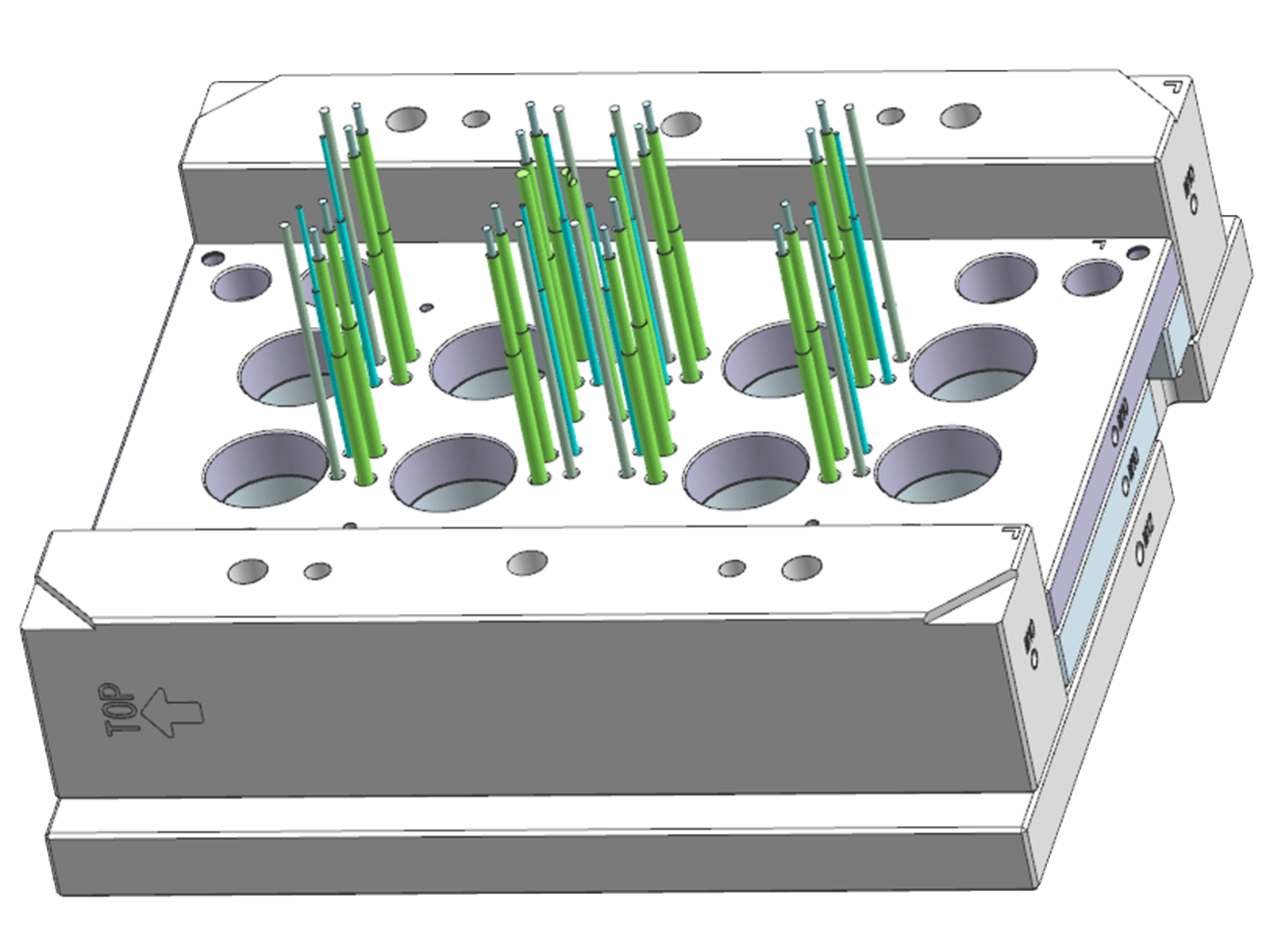

Professional 3D design software (including Pro/E, UG, and SolidWorks) is utilized to develop comprehensive mold structures, encompassing critical components such as cavities, cores, runner systems, gates, cooling channels, and ejection mechanisms.

Leveraging the expertise of mold engineers with over a decade of experience, combined with practical trial injection validation, any identified flaws are addressed through iterative design refinements until perfection is achieved, ensuring the mold meets the precision requirements of optical lenses.

We utilize industry-leading design software to ensure precision and efficiency in mold design.

Parametric modeling and assembly design deliver powerful 3D design capabilities, ensuring mold structure precision and reliability.

Integrated CAD/CAM/CAE solutions provide comprehensive end-to-end support from conceptual design to engineering analysis.

An intuitive user interface coupled with robust modeling functions enhances design efficiency and accelerates development cycles.

Specialized injection molding simulation analyzes and resolves potential production issues, optimizing mold design performance.

Essential components of precision mold design, ensuring accurate optical lens formation.

The core molding components determining optical lens geometry and dimensional accuracy, manufactured with high-precision machining and mirror polishing techniques.

Channels guiding molten plastic into cavities, optimized for uniform material filling and minimized molding defects.

Precision-engineered cooling channels ensuring uniform temperature distribution, reducing cycle time and enhancing production efficiency.

Ensures damage-free demolding of formed optical lenses while maintaining surface quality.

Leveraging extensive experience and specialized expertise, we deliver exceptional mold design solutions.

Two decades of mold design expertise enable us to tackle complex structural challenges with proven methodologies.

Swift adaptation to client needs accelerates design cycles and ensures timely project delivery.

Optimized mold designs requiring zero post-modifications, saving time and reducing costs.

Rigorous quality control protocols guarantee mold designs consistently meet the highest industry standards.

Our professional team is ready to deliver high-quality mold design services to ensure the successful execution of your optical lens project.

Contact us for a quotationAsahi Optics welcomes your questions, inquires and feedback. Please use the form below or contact us at any of the addresses below. Our sales team will get back to you shortly.