Street lighting is the nervous system of a modern city, playing a pivotal role in ensuring traffic safety, enhancing urban security, and reducing energy consumption. However, for procurement officers and lighting engineers, the market presents a complex challenge: with thousands of manufacturers offering visually similar products, what is street lighting quality in reality?

Many buyers fall into the trap of judging a fixture solely by its wattage or the brand of the LED chip. But the reality is that a high-quality street lamp is a sophisticated system where optical design (lenses), thermal management, and structural integrity must work in perfect harmony. A poorly designed fixture might be bright, but it can cause dangerous glare, "zebra striping" on the road, or fail prematurely due to heat buildup. In this guide, we will look beyond the spec sheet to help you understand the core indicators of quality—specifically focusing on how optical performance defines the true value of a street light.

1. What Defines High-Quality Street Lighting?

In the era of traditional high-pressure sodium (HPS) or metal halide lamps, judging quality was relatively straightforward—mostly revolving around the durability of the ballast and the bulb's lifespan. However, the LED revolution has fundamentally shifted the parameters of assessment. Today, a high-quality street light is defined not just by whether it turns on, but by how effectively it converts electricity into usable light and how precisely it directs that light onto the roadway. To evaluate a modern luminaire, buyers must look beyond the basic wattage and examine two critical technical pillars: system luminous efficacy and optical precision.

Learn more about street light content

Luminous Efficacy (lm/W) vs. Raw Brightness

A common misconception among inexperienced buyers is equating high wattage with high brightness. This is a costly mistake. The true measure of performance is Luminous Efficacy, measured in lumens per watt (lm/W). It represents the efficiency of the conversion from electrical power to visible light.

However, professional buyers must distinguish between "LED Source Efficacy" and "Luminaire System Efficacy." A datasheet might claim 160 lm/W based on the LED chip alone, but after accounting for optical loss (through the lens and glass) and thermal loss, the actual system efficacy might drop to 120 lm/W. High-quality street lamps prioritize system efficacy, ensuring that energy is not wasted as heat. A fixture with higher efficacy reduces the total power load on the city's grid and significantly lowers electricity costs over the product's lifecycle. Therefore, a 100W lamp with superior efficacy can often outperform a 150W lamp of inferior quality, providing the same brightness with 33% less energy consumption.

The Critical Role of Optical Design

If the LED chip is the heart of the street lamp, the optical lens is its brain. Without a sophisticated optical system, an LED is simply a floodlight that scatters photons in all directions—lighting up the sky, the surrounding trees, and the driver’s eyes, rather than the road surface. This is where optical design becomes the deciding factor in fixture quality.

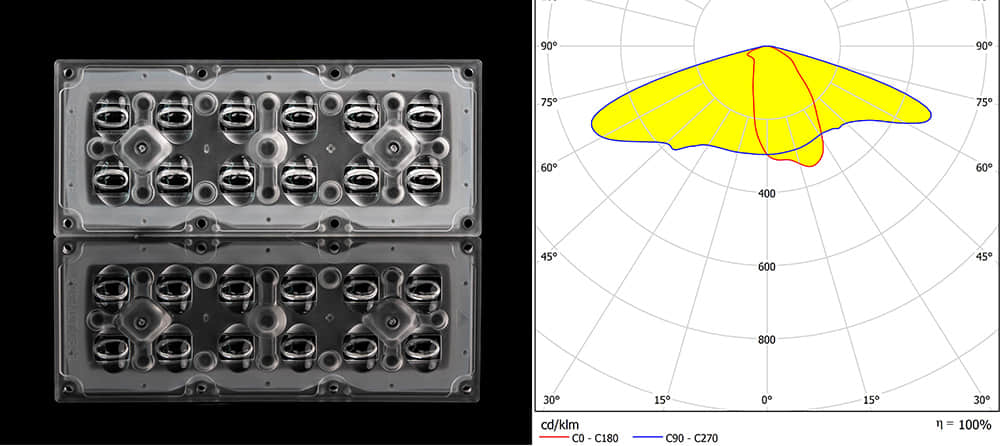

High-quality street lights utilize precision-engineered lenses to manage the direction of every light ray. The goal is to achieve high "Target Efficiency," meaning the maximum percentage of light output lands exactly within the target area (the road lanes). Poor optics result in light pollution and dark spots between poles. By utilizing advanced street light optics, manufacturers can shape the beam into specific patterns (such as rectangular or "batwing" distributions) that match the road geometry. This capability allows for wider pole spacing—reducing the number of poles needed for a project—and ensures compliance with international lighting standards.

2. 5 Key Indicators to Judge the Quality of Street Lamps

To evaluate whether a street lighting fixture is truly "engineering grade," buyers must scrutinize specific technical metrics. Here are the critical indicators that determine performance and reliability.

Light Distribution & Uniformity (ISO/CIE Standards)

The most visible difference between a premium street light and a cheap knockoff is how the light lands on the ground. This is governed by the fixture's Light Distribution Curve.

Standard street lighting usually requires Type II or Type III distribution patterns (as defined by IESNA standards). Type II is ideal for narrow roads and pathways, focusing light longitudinally along the street, while Type III pushes light further across wider roadways. A common issue with low-quality lenses is the "Zebra Effect"—alternating bright and dark stripes on the road. This not only looks unprofessional but creates dangerous visual fatigue for drivers.

High-quality fixtures prioritize Uniformity Ratio of Illuminance (U0). This metric ensures that the brightness is consistent across the entire coverage area. Achieving this requires precision-molded lenses, such as Type II Medium beam angle lenses, which are specifically designed to spread light evenly while maintaining high intensity where it is needed most. When sourcing fixtures, always request an IES file to simulate the uniformity in software like Dialux.

Glare Control (UGR & Cutoff Classifications)

Brightness without control is hazard. Glare is one of the biggest safety risks in roadway lighting, as it can temporarily blind drivers or pedestrians. Judging quality involves checking the Cutoff Classification of the luminaire:

-

Non-Cutoff: Allows light to scatter upwards (causes light pollution).

-

Semi-Cutoff: Allows some light at high angles.

-

Full-Cutoff: Strictly limits light above 90 degrees, eliminating uplight and significantly reducing glare.

For projects near residential areas or high-speed roads, fixtures with a low UGR (Unified Glare Rating) are non-negotiable. High-quality manufacturers achieve this not by dimming the light, but by using advanced optical designs—such as specialized surface textures on the lens or "cutoff" physical designs—to shield the light source from direct view while maintaining ground illuminance.

Thermal Management & Heat Dissipation

While optics determine performance, heat determines lifespan. LED chips are sensitive to temperature; excessive heat at the junction point leads to rapid lumen depreciation (the light gets dimmer over time) and color shifting (the light turns blue or pink).

A high-quality street lamp acts as a giant heatsink. When judging quality, look at the housing design. It should be made of die-cast aluminum with ample surface area (fins) to facilitate air convection. But the design must also be self-cleaning—poorly designed fins can trap dust and leaves, acting as an insulating blanket that overheats the fixture. A superior design ensures that the junction temperature (Tj) remains well below the chip’s maximum rating (usually <85°C) even during hot summer nights, guaranteeing the claimed 50,000+ hours of operation.

Waterproof & Dustproof Ratings (IP & IK Ratings)

Outdoor lighting faces harsh realities: torrential rain, snow, dust storms, and physical impacts. Therefore, the enclosure rating is a definitive quality marker.

-

IP Rating (Ingress Protection): A quality street lamp must be at least IP65, though IP66 is the preferred standard for professional road lighting. This ensures that powerful water jets and dust cannot penetrate the housing or the optical module.

-

Pro Tip: Pay attention to the optical module itself. Some designs use integrated lenses with silicone gaskets that create a sealed environment for the LED chips, protecting them from humidity and sulfurization.

-

-

IK Rating (Impact Protection): This measures resistance to mechanical impact. For street lights prone to vandalism or hail, an IK08 or IK10 rating is essential. This is where the choice of lens material (discussed below) becomes critical.

More detailed introduction to IP rating

Material Quality: PC vs. PMMA Lenses

The lens material is often the first thing to fail in cheap fixtures. Over time, inferior materials degrade under UV radiation from the sun and the LED itself, turning yellow and brittle. This yellowing drastically reduces light output and alters the color temperature.

-

PMMA (Acrylic): Has high light transmission and natural UV resistance but is brittle (low IK rating). It can crack easily under hail or impact.

-

PC (Polycarbonate): virtually unbreakable (high IK rating) and heat resistant. However, raw PC yellows quickly.

Top-tier manufacturers use Optical-Grade Polycarbonate with UV stabilizers (from suppliers like Mitsubishi or Teijin). This ensures the lens maintains high transparency and structural integrity for 5-10 years outdoors.

3. Why the Lens is the Most Underrated Component in Street Lighting

While the LED chip generates the light, the lens dictates where that light goes and how effectively it is used.

A common industry pitfall is pairing a high-end LED chip (like Cree or Lumileds) with a cheap, poorly molded lens. The result is a system that wastes energy scattering light into the sky (light pollution) or creates uneven patches on the road. The difference lies in Mold Precision.

Producing a high-performance street light lens requires optical mold manufacturing with micron-level accuracy. A rough mold surface results in light scattering and reduced transmission efficiency. Furthermore, standard off-the-shelf lenses may not fit every unique road geometry or pole height. This is why leading project developers often opt for custom optical lens design services. By customizing the lens surface, engineers can fine-tune the beam angle to perfectly match the specific width of the road and the spacing of the poles, maximizing energy savings and ensuring total compliance with local lighting regulations.

4. Conclusion

Selecting the right street lighting solution is a strategic investment that balances initial cost against long-term performance and maintenance. As we have explored in this guide, the true quality of a street lamp is not defined by its exterior housing alone, but by the "invisible" engineering details: the precision of the optical lens, the efficiency of the thermal management system, and the durability of the materials against harsh environments.

For professional buyers and lighting designers, prioritizing high-quality optical components is the surest way to guarantee project success. A superior lens does more than just transmit light; it ensures driver safety through glare control, reduces energy waste through precise distribution, and extends the fixture's lifespan.

At Asahi Optics, we believe that the lens is the heart of any high-performance fixture. Whether you are looking for standard IP66 rated street light lenses to upgrade your current product line, or require a fully customized optical design for a specific roadway project, our engineering team is ready to assist.

Contact us today to discuss how we can optimize your optical performance.