Over 30% of LED street lights in past urban lighting projects underperformed due to poorly matched optical components. This resulted in dark spots, excessive glare, and wasted energy, costing cities tens of thousands of dollars in unnecessary replacement costs.

Therefore, choosing the right LED street light lens is crucial. This article will explain how to select high-performance LED lenses for your urban lighting needs by focusing on two key technical factors: beam angle and material.

Three Key Factors for Street light Lens Selection

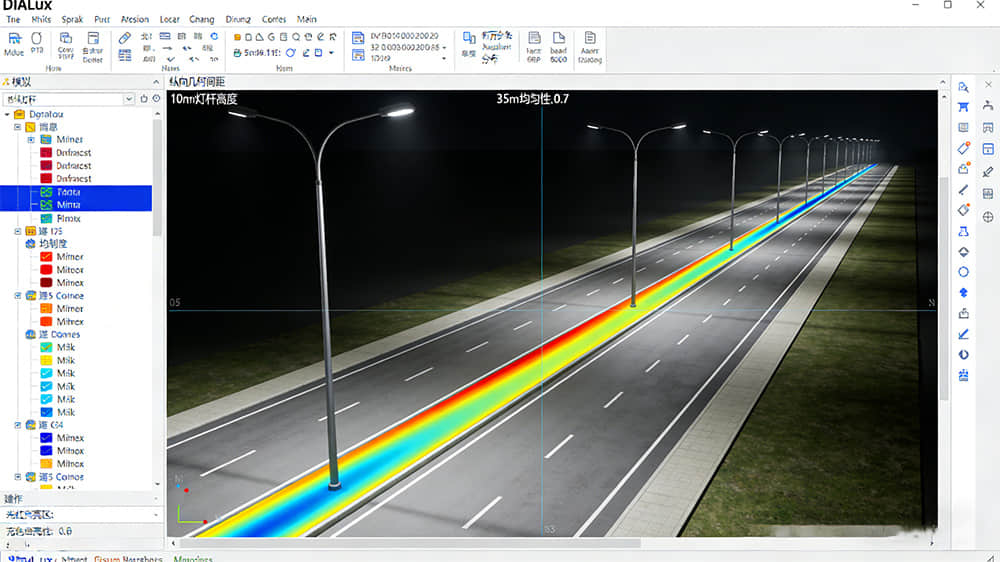

1. Beam Angle and Light Distribution

Street light lenses are categorized by beam type (I-V), which varies depending on the extent of light spread:

- Type I (Linear): Best suited for bike paths and narrow passageways (symmetrical forward projection)

- Type II (Curbside): Best suited for sidewalks and narrow streets (asymmetrical medium-width distribution). Use Type II in residential areas to minimize light interference.

- Type III (Intersection): Wider projection, best suited for crosswalks and medium-width roads (wide asymmetrical distribution)

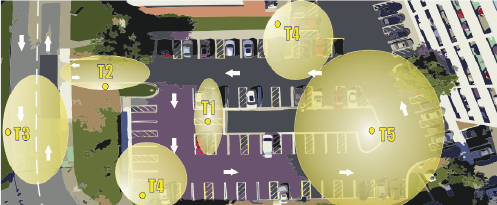

- Type IV (Perimeter): Best suited for parking lots and industrial areas (forward-projected semicircular pattern)

- Type V (Square): Best suited for roundabouts and plazas (360° uniform circular/square pattern)

2. Lens Material: PMMA, PC, and Glass

Material Optimal Application Advantages Disadvantages

- PMMA Suitable for mild climates High clarity, 90% Light transmittance above 100% but easily scratched.

- PC (polycarbonate) is suitable for high-impact areas. It is shatterproof and UV-resistant.

- Glass is suitable for high-end projects. It offers excellent optical precision but is heavy and fragile.

A 4-step framework for selecting the right lens

Step 1: Understand lighting requirements.

For example, you can choose the low-glare Type II for pedestrian areas or the wide-angle projection Type III for vehicle road areas.

Step 2: Test prototypes.

Asahi offers low-MOQ trial batches to verify performance before mass production.

Step 3: Verify weather resistance.

Check IK rating (impact resistance) and IP65+ (dust/waterproof).

Step 4: Optimize energy efficiency.

Look for anti-glare designs to reduce light waste.

Prioritize beam control and vandal-resistant materials. Customization is available for more specific requirements! Avoid using generic lenses, which can lead to uneven lighting.